News

Short Path Distillation - Buying Guide

Short-path distillation is a new product designed and developed by our company to meet market demand. The device has simple structure, small floor space, high evaporation efficiency and high recovery efficiency, and is mainly used in the fractionation process.

Note on using short-path distillation:

1. No load is not suitable for high speed operation;

2. Keep the speed control and the motor dry, because the life of the electrical box has a great influence on the surrounding humidity and temperature;

3. The ground wire must be well grounded, and the high temperature bath must be connected to the open switch;

4. There may still be electric shock within 5 minutes after the power is turned off, due to the discharge of the inverter or capacitor;

5. Please avoid damage to the glass by hard objects such as watches and rings when operating the instrument;

6. When the glass reactor needs heating, it should be gradually heated. Especially when heating at high temperature, it is generally recommended to use heat-conducting oil with little damage to the human body.

Short-path distillation model

| Image | Product Name | Product Parameters |

|

SPD-2L Short path distillation |

1. Heating capacity: 20000ml

2. Vacuum degree: 0.098Mpa

3. Material: G3.3

|

|

SDP-5L Short path distillation |

1. Heating capacity: 50000ml

2. Vacuum degree: 0.098Mpa

3. Material: G3.3

|

|

SPD-10L Short path distillation |

1. Heating capacity: 100000ml

2. Vacuum degree: 0.098Mpa

3. Material: G3.3

|

|

SPD-20L Short path distillation |

1. Heating capacity: 200000ml

2. Vacuum degree: 0.098Mpa

3. Material: G3.3

|

Advantages of short-path distillation equipment

1. The product is made of high quality borosilicate material.

2. The glass parts are connected by a matte port, which is easy to operate and has good sealing performance.

3. The structural size can be customized according to the special needs of customers.

4. High-precision transmission and mechanical seal design to ensure long-term smooth operation of equipment

5. The evaporation cylinder is integrally formed without intermediate flange connection.

6. The surface of the cylinder has a high surface finish and is not easy to stick.

7. Unique liquid distributor and splash-proof device design to ensure product quality

Optional auxiliary equipment

| Product Image | Features |

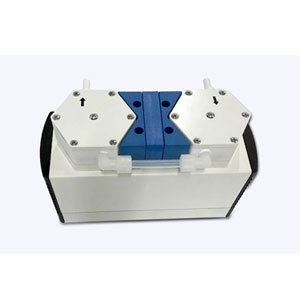

Diaphragm pump |

1. Chemical resistance

2. Non-polluting, maintenance-free

3. Low noise, low vibration

4. Overheat protection

|

Rotary vane vacuum pump |

1. Rotary vane vacuum pump is small in size, light in weight and low in noise

2. With gas ball valve, can remove a small amount of water vapor

3. With automatic anti-return oil double safety device

4. Can be used alone or as a fore pump and pre-pump for all types of high vacuum systems

|

Vertical Type Circulating Water Vacuum Pump |

1. Multi-purpose machine

2. Corrosion resistance

3. Low noise

4. Stable performance

|

Desktop Circulating Water Vacuum Pump |

1. Equipped with a circulation device, the vacuum is stable, the appearance is beautiful, and it is small and exquisite.

2. This product has double tapping and can be used alone or in parallel to two vacuum gauges.

3. The main engine is made of stainless steel and the box is made of engineering plastic. Anti-corrosion, no pollution, low noise, easy to move.

|

Low temperature cooling liquid circulating pump |

1.Corrosion resistance

2. Cooling speed is fast

3. Large cooling power

4. Easy to operate

|

Low temperature constant temperature reaction bath |

1. Cooling speed is fast

2. Low noise

3. Advanced performance

4. Reliable quality

|

Packaging picture

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.