Grouped equipment

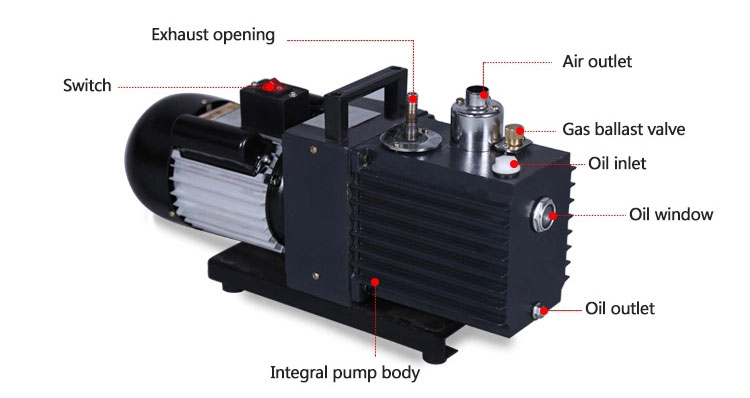

2xz-2 Rotary Vane Vacuum Pump

The 2XZ pump has the advantages of small size, light weight, low noise and easy start-up. In addition, means are provided to prevent oil leakage and oil leakage from the shaft seal to the polluted environment.

Structure

The rotary vane vacuum pump is composed of pump body, rotor, rotary vane, end cover, spring, etc. A rotor is eccentrically installed in the cavity of the rotary vane pump, and the outer circle of the rotor is tangent to the inner surface of the pump cavity (there is a small difference between the two gap), and two rotating vanes with springs are installed in the rotor slot. When rotating, relying on the centrifugal force and the tension of the spring to keep the top of the rotary vane in contact with the inner wall of the pump chamber, the rotation of the rotor drives the rotary vane to slide along the inner wall of the pump chamber.

Working Principle

The working principle of the rotary vane vacuum pump is to use the rotor to rotate, and the volume of the rotary vane in the rotor groove changes with the centrifugal force and the shape of the inner surface of the stator, so as to discharge the gas and vacuumize. The specific working process is as follows:

The rotary vane of the rotary vane pump divides the crescent-shaped space surrounded by the rotor, the pump chamber and the two end covers into three parts A, B and C. When the rotor rotates, the volume of the space A communicating with the suction port gradually increases. The increased one is in the process of inhalation; the volume of the space C communicating with the exhaust port is gradually shrinking, and it is in the process of exhausting; the volume of the space B in the middle is also gradually reduced, and it is in the process of compression.

Since the volume of space A gradually increases and the gas pressure decreases, the external gas pressure at the inlet of the pump is higher than the pressure in space A, so the gas is inhaled; when space A is isolated from the suction port, it turns to the position of space B , the gas begins to be compressed, the volume gradually shrinks, and finally communicates with the exhaust port. When the compressed gas exceeds the exhaust pressure, the exhaust valve is pushed open by the compressed gas, and the gas passes through the oil layer in the tank and is discharged into the atmosphere. Through the continuous operation of the vacuum pump, the purpose of continuous pumping is achieved.

Installation

1. The pump should be placed in a dry, ventilated place.

2. The pump has a handle on the top and four rubber posts on the bottom, which are portable. Therefore, in most cases, the pump is placed only on a flat and stable surface.

3. To wire the motor, please pay attention to the direction of rotation from the fan end of the motor. The direction of rotation should be clockwise.

4. The diameter of the pipe and the inlet of the pump should not be smaller than the diameter of the pump inlet and pipe. The pipe should be short and should have as little bending as possible to reduce the loss of pumping speed. At the same time, attention should be paid to pipe leakage If a rubber tube is used, it is best to desulfurize the tube.

5. When the pump is started, the air inlet is open to the atmosphere and a small amount of oil mist will be generated. It may affect the working environment and use plastic tubing to direct it to the open air.

6. The pump is equipped with a device that prevents oil absorption when stopped. Therefore, there is no need to install a magnetic valve on the inlet port.

Application

1. The pump is one of the basic equipment for discharging the sealed container. It can be used primarily as a stand-alone pump for booster pump diffusion pumps and molecular pumps, or as a pre-pump for holding pumps and different types of pumps for vacuum systems. Therefore, it can be applied to the electric vacuum industry, vacuum bottle manufacturing, vacuum welding and as an accessory for precision instruments or meters that require vacuum. Due to its small size, light weight and quiet operation, it is more suitable for laboratory use.

2. Allow the pump to work continuously for several hours at an ambient temperature of 5 °C - 40 °C and an inlet pressure of 1230 Pa. The pumped gas containing the moisture of the ballast valve with a relative humidity greater than 90% should be opened.

3. The pump inlet should be open to the atmosphere for a continuous operation of no more than three minutes.

4. Pumps are not suitable for pumping peroxides, poisons, explosive and corrosive gases, and gases that react chemically with pump oil contain dust particles.

Maintain

(1) Wipe all parts.

(2) Place the blades into the respective slots of the rotor, then place the advanced rotor into the stator, place the cover on the stator, and install the pins, keys and sleeves in their original positions. The rotor should be rotated evenly by hand.

(3) Repeat the same process for the lower rotor again.

(4) Put the impeller and check valve of the check valve back in place. The plane of the valve head should point to the oil hole. The impeller is stopped by hand while rotating the rotor. The oil holes should be alternately closed and opened by the valve, and then the maximum opening height of the valve head plane is adjusted to a value of 0.8-1.2 mm.

(5) Place the exhaust valve and the oil baffle on the top of the pump body.

(6) Mount the pump body, key, bushing and motor on the frame.

(7) Cover the pump body with a fuel tank.

(8) Insert the intake pipe and the gas ballast valve and tighten the flange for fixing.

Application

1. The pump is one of the basic equipment for discharging the sealed container. It can be used primarily as a stand-alone pump for booster pump diffusion pumps and molecular pumps, or as a pre-pump for holding pumps and different types of pumps for vacuum systems. Therefore, it can be applied to the electric vacuum industry, vacuum bottle manufacturing, vacuum welding and as an accessory for precision instruments or meters that require vacuum. Due to its small size, light weight and quiet operation, it is more suitable for laboratory use.

2. Allow the pump to work continuously for several hours at an ambient temperature of 5 °C - 40 °C and an inlet pressure of 1230 Pa. The pumped gas containing the moisture of the ballast valve with a relative humidity greater than 90% should be opened.

3. The pump inlet should be open to the atmosphere for a continuous operation of no more than three minutes.

4. Pumps are not suitable for pumping peroxides, poisons, explosive and corrosive gases, and gases that react chemically with pump oil contain dust particles.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.