News

Laboratory short path distillation - operating processes and applications

Short-path distillation is a new product designed and developed by our company to meet market demand. The device has simple structure, small floor space, high evaporation efficiency and high recovery efficiency, and is mainly used in the fractionation process.

Main application areas: food, pharmaceuticals, fine chemicals, electronic materials, plastic engineering and polymers (such as polyols, fatty acids, polyphenols, polyurethanes, epoxies, lactic acid, monoglycerides, flavors, heavy oils and paraffin oils) Separation and purification, etc.

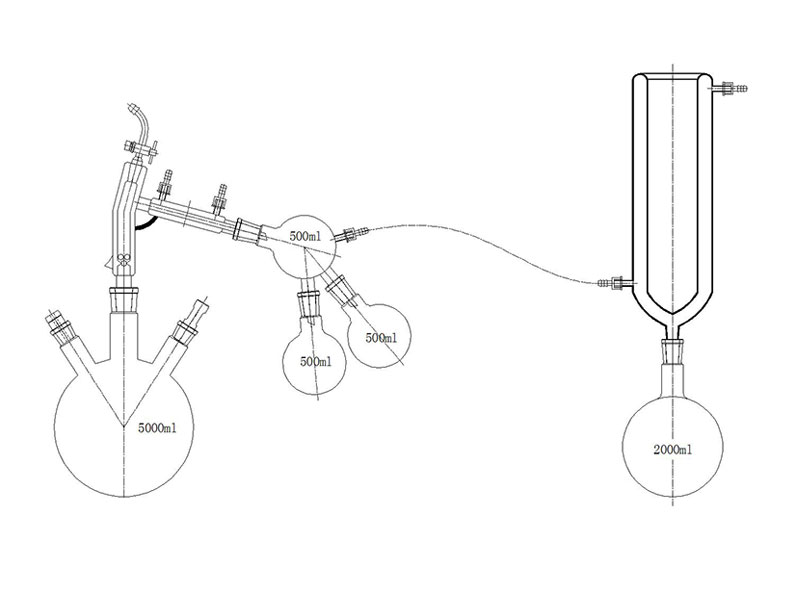

Short-path distillation main components

Fractionation is a method of separating mixtures of several different boiling points; heating a mixture to separate the different boiling points of the components in the mixture into a relatively pure single material process. No new substances are formed in the process, but the original substances are separated and belong to physical changes.

Fractionation is actually a multiple distillation, which is more suitable for separating and purifying liquid organic mixtures with similar boiling points.

Such as fractional distillation of coal tar; fractionation of petroleum. When the boiling points of the substances are very close, about 20 degrees difference, the simple distillation method cannot be used, and the fractionation method can be used instead. The small column of the fractionation column provides a large surface area to condense with the vapor. Fractionation is the method of using a fractionation column to perform multiple gasification-condensation processes in one operation.

Therefore, fractionation is actually multiple distillations. It is more suitable for separating and purifying liquid organic mixtures with similar boiling points.

The principle of fractionation: after the mixture boils, the vapor enters the fractionation column and is partially condensed. The condensate is in contact with the rising vapor on the way down, the two exchange heat, the high-boiling components in the steam are condensed, and the low-boiling components are still vapor. Ascending, while the low-boiling components in the condensate are heated and vaporized, and the high-boiling components are still in a liquid state. The result is an increase in the low boiling component of the rising vapor and an increase in the high boiling component of the descending condensate. Thus, after multiple heat exchanges, it is equivalent to a plurality of ordinary distillations. As a result, the vapor of the low-boiling component rises and is distilled off; the high-boiling component continuously flows back into the distillation bottle to separate them.

Our company currently has a series of 2L, 5L, 10L, 20L specifications, so you can choose according to actual needs. In addition, the supporting products can be provided by our company to facilitate your entire experiment.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.