Grouped equipment

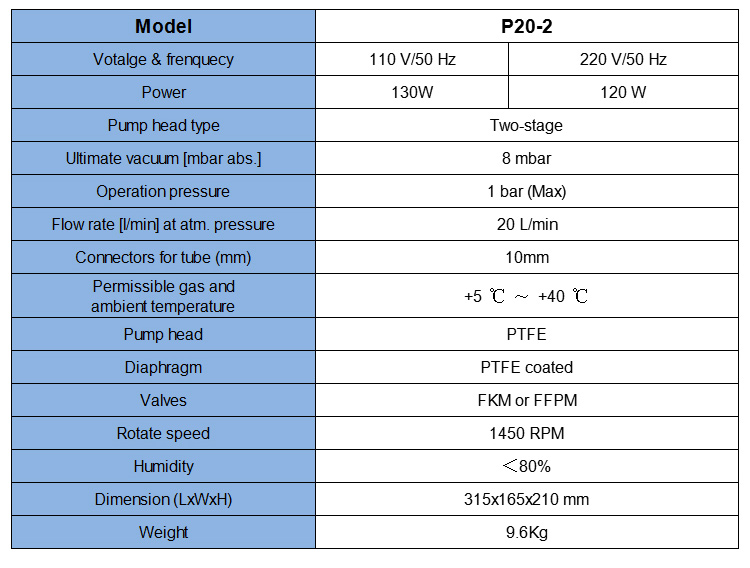

P20 vacuum diaphragm pump

P20 vacuum diaphragm pump is a gas-based two-stage pump. All parts in contact with gas are PTFE materials. It has strong corrosion resistance and wide application. It can completely replace water circulation pump and is suitable for corrosion in chemical, pharmaceutical, petrochemical and other industries. The gas is treated, such as suction filtration, vacuum distillation, rotary evaporation, vacuum concentration, centrifugal concentration, solid phase extraction, and the like.

P20 vacuum diaphragm pump schematic

Feature

1. Chemical resistance: Corrosion-resistant vacuum pump adopts special diaphragm (PTFE coating on membrane surface) and pump head design, including all joints and pipes. Gas contact parts are made of imported PTFE material, so they are resistant to most corrosive gases. At the same time, electrical The switch and the outer casing are also treated with anti-corrosion treatment. In particular, the transmission mechanism and the circuit part are made of corrosion-resistant materials to form a closed space, completely isolated from the external environment, so that the vacuum pump is not only resistant to corrosive media, but also suitable for corrosive environments, completely solving the vacuum pump. Chemical resistance issues.

2. Non-polluting, maintenance-free: The diaphragm vacuum pump can completely recover the solvent, eliminate the environmental pollution caused by toxic and harmful organic solvents, and the health hazard to the operators and nearby people, even if the mixed solvent can be highly recovered; the diaphragm pump is a kind of dry, The dry, oil-free pump keeps the lab clean and quiet, eliminating the need for regular cleaning, changing tubes and changing water. The diaphragm vacuum pump is 100% maintenance free.

3. Low noise, low vibration: Corrosion-resistant vacuum pump motor directly drives the power transmission, without intermediate transmission parts, plus the low stroke of the diaphragm and low noise characteristics, so that the product noise can be kept below 70dB.

4. Overheat protection: Each product is equipped with a temperature protection switch. When the temperature in the body is too high, it will automatically shut down, wait for the temperature to cool and then start it by itself to ensure the stability and safety of the system.

User's guidance

1. When all tubes are properly connected to the inlet and outlet, turn on the power switch.

2. After use, remove the vacuum cleaner and continue to run the vacuum pump for at least two minutes to extend the life of the pump.

Note:

A. One. When the pump is used as a vacuum pump, the outlet cannot be blocked.

B. Bay prohibits the use of pumps to transport liquid or solid particles.

C. Do not use in rooms where the equipment is explosion-proof.

d. It is forbidden to handle samples (ie explosive samples) that have exploded due to collisions, friction, heat or sparks.

That is, it is forbidden to use the pump to generate both vacuum and pressure.

F. The suction port of the pump should not be connected to overpressure.

G. If the pump does not work, turn on the switch, immediately turn off the switch, remove the vacuum and turn it on again; if the pump still does not work, contact our technician.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.