News

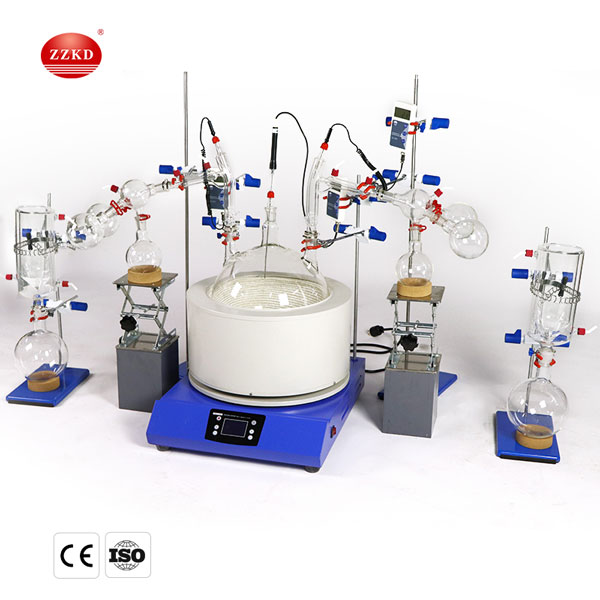

Full Bore Short Path Distillation Kit For Sale In Canada

Before the first use of the cdu 1000 distillation, it is necessary to understand its working principle and precautions in advance to avoid misoperation during use and cause losses. The following is a brief introduction to the full bore short path distillation kit.

Short path distillation is a distillation process equipment that operates under high vacuum. The short-range molecular distiller is divided into three types according to the form of the film scraper: rolling film type, sliding film type, hinged film type, according to the viscosity of the material and the processing properties to choose the appropriate film scraper.

Full bore short path distillation kit is equipped with lab oratory water circulation pump, short path distillation vacuum pressure system.

Short Path Distillation Working Principle:

The driving force of the steam flow is the pressure difference between the boiling film and the condensing surface, and a small pressure drop will cause the steam to flow. Operating at 1 mbar and requiring a short distance between the boiling surface and the condensing surface, a still made according to this principle is called a short path still. Short path stills (molecular distillation) have a built-in condenser opposite the heating surface and bring the operating pressure down to 0.001 mbar.

The short-path distiller is a thermal separation technology process that works under the pressure of 1~0.001mbar. It has a lower boiling temperature and is suitable for heat-sensitive and high-boiling materials. Its basic composition: a cylindrical cylinder with a heating jacket, a rotor and a built-in condenser; a film scraper and an anti-splash device are precisely installed on the fixed frame of the rotor. The built-in condenser is located in the center of the evaporator, and the rotor rotates between the cylindrical barrel and the condenser.

A short-path still consists of an outermost heated vertical cylinder with a central condenser located in it and a wiper that rotates between the still and the condenser.

The Distillation Process Is:

The material is added from the top of the evaporator, and is continuously and evenly distributed on the heating surface by the material liquid distributor on the rotor, and then the film scraper scrapes the material liquid into a thin, turbulent liquid film, and spirally Push down. During this process, light molecules escaping from the surface of the heating surface condense into liquid on the built-in condenser after a short route and almost without collision, and flow down the condenser tube, passing through the evaporator at the bottom of the evaporator. The discharge pipe is discharged; the residual liquid, that is, the heavy molecules, is collected in the circular channel under the heating zone, and then flows out through the discharge pipe on the side.

Short path stills are also more suitable for molecular distillation. Molecular flow is directed from the heating surface to the condenser surface.

The Short-Path Distillation Process Can Be Made In The Following Four Steps:

1. Molecules diffuse from the bulk of the liquid phase to the evaporation surface:

Under normal circumstances, the diffusion rate in the liquid phase is the most important factor to control the molecular distillation rate, and the thickness of the liquid layer should be reduced as much as possible and the flow of the liquid layer should be strengthened.

2. Free evaporation of molecules on the surface of the liquid layer:

The evaporation rate increases with the increase of temperature, but the separation factor sometimes decreases with the increase of temperature. Therefore, a more economical and reasonable distillation temperature should be selected on the premise of the thermal stability of the processed material.

3. Molecules fly from the evaporation surface to the condensation surface:

In the process of flying from the evaporation surface to the condensation surface, the vapor molecules may collide with each other or with the air molecules remaining between the two surfaces. Since the evaporation molecules are much heavier than the air molecules, and most of them have the same direction of motion, their collisions have little effect on the direction of the flight and the evaporation speed. The residual gas molecules are in a disordered thermal motion state between the two sides, so the number of residual gas molecules is the main factor affecting the flying direction and evaporation speed.

4. Molecules condense on the condensation surface:

As long as there is a sufficient temperature difference between the hot and cold sides (usually 70~100°C), and the form of the condensation surface is reasonable and smooth, it is considered that the condensation step can be completed in an instant, so it is very important to choose a reasonable form of the condenser.

How To Buy a Full Bore Short Path Distillation Kit?

To buy the most cost-effective ready short path distillation kit, an ideal solution for short path distillation kit is necessary, which will save unnecessary business expenditures and time. ZZKD has highly skilled professionals who are always ready to help you regarding all your ready short path distillation kit-related queries. We are sincerely looking for your coming.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.