News

Laboratory essential equipment, bench-top circulating water vacuum pump

The desktop circulating water vacuum pump is also called a water circulation vacuum pump which is a rough vacuum pump. It has an ultimate vacuum of 2000-4000 Pa and a tandem atmospheric injector of 270-670 Pa. The water circulation pump can also be used as a compressor, called a water circulation compressor, which is a low pressure compressor with a pressure range of 1-2 x 105 Pascal.

The bench-top circulating water vacuum pump is the most commonly used in laboratories. The laboratory vacuum pump has low noise and stable performance. It also has the advantages of small size, small footprint and light weight. At the same time, as a common vacuum equipment for short-path distillation, it supports the perfect operation of the entire short-path distillation system. Its advantages, just in line with the definition of short-path distillation unit, is a device system that only needs a small distance to complete the distillation, fractionation and purification process.

Product Features of Desktop Circulating Water Vacuum Pump:

1.This machine adopts double taps and double display, which can be used separately or in parallel;

2. The pump body and impeller (six-flow channel, double seal) are stamped and formed by stainless steel plate, which is exquisite and beautiful; the shell, the water tank, the three-way, the check valve, the jet and the air suction nozzle are special engineering plastics;

3.equipped with a special fluid muffler to reduce the friction noise of gas and liquid in the water, so that the vacuum is higher and more stable.

4. Acid, alkali, solvent corrosion

5. It has no pollution, low noise and convenient movement. It can also be equipped with vacuum regulating valve according to user needs, which is easy to operate;

6. Recycling water to save valuable water resources; saving more than 35% of electricity compared to other vacuum pumps

7.Fluororubber seal, no corrosive gas intrusion inside the motor

8. The water in the water tank should be replaced regularly to ensure the purity of the water, ensure the vacuum and avoid the scale.

9. It can be used to extract corrosive gases, and the water change cycle needs to be shortened.

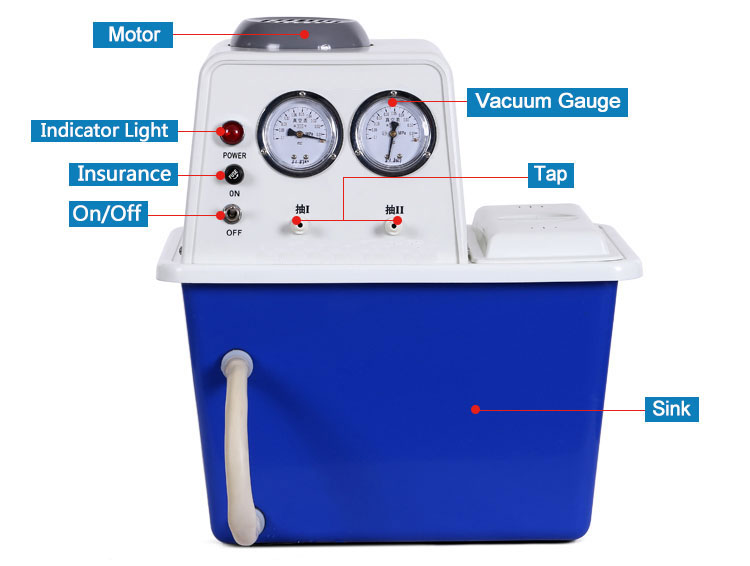

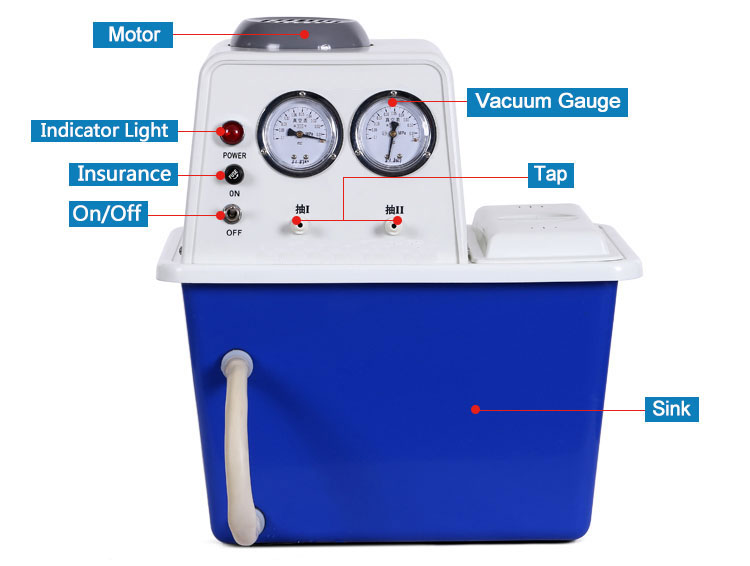

bench-top circulating water vacuum pump

bench-top circulating water vacuum pump

How to use the desktop circulating water vacuum pump:

1. Prepare for work. Place the SHZ circulating water multi-purpose vacuum pump on the workbench. When using for the first time, open the top cover of the water tank to inject clean cold water (can also add water through the drain hose), and stop when the water surface is about to rise to the height of the overflow nozzle behind the water tank. Add water, repeat the boot can no longer add water. However, the water is replaced once a week for the longest time. If the water pollution is serious and the usage rate is high, the time for replacing the water can be shortened. The ultimate goal is to keep the water in the water tank clean.

2. Vacuuming work. The suction sleeve of the equipment that needs to be vacuumed is tightly sleeved on the circulating water type multi-purpose vacuum pump suction nozzle, the circulation switch is turned off, the power is turned on, the power switch is turned on, and the vacuuming operation is started, corresponding to the suction nozzle. The vacuum gauge can observe the degree of vacuum.

3. When the circulating water type multi-purpose vacuum pump needs to work continuously for a long time, the water temperature in the water tank will rise, affecting the degree of vacuum. At this time, the drain hose and the water source (tap water) can be connected, and the overflow nozzle serves as a drain outlet. By properly controlling the tap water flow, the water temperature in the tank can be kept from rising and the vacuum can be stabilized.

4. When it is necessary to provide cooling circulating water for the reaction device, on the basis of the operation of the third step above, the water inlet and outlet pipes of the device to be cooled are respectively connected to the circulating water outlet and the water inlet at the back of the machine. Turn the circulating water switch to the ON position to realize the circulating cooling water supply.

Desktop circulating water vacuum pump maintenance:

1. Check the oil level position frequently. If it does not meet the requirements, it must be adjusted to meet the requirements. When operating with a vacuum pump, the oil level is at the center of the oil standard.

2. Check the oil quality frequently and find that the oil should be replaced in time to ensure that the vacuum pump works normally.

3. The oil change period is considered according to the actual use conditions and whether the performance requirements can be met, at the discretion of the user. Generally, when the new vacuum pump is used to remove clean and dry gas, it is recommended to change the oil once every 100 hours. After the black metal powder is not visible in the oil, the oil change period can be extended in the future.

Model of desktop circulating water pump

| Model | SHZ-C | SHZ-C | SHZ-95B |

| Power(W) | 370 | ||

| Voltage(V/Hz) | 110V 50/60Hz | ||

| Flow(L/min) | 80 | ||

| Body Material | 1cr18 | polypropylene | Anti-corrosive |

| Lift(m) | 12 | ||

| Max. Vacuum(Mpa) | 0.098 | ||

| Sucking rate for single tap (L/min) | 10 | ||

| Quantity of tap(Pcs) | 5 | 3 | 5 |

| Tank capacity(L) | 50 | ||

| Dimension(mm) | 450*340*870 | 450*340*840 | |

| Weight(kg) | 37 | ||

| Security performance | check-valve | ||

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.