News

Where To Buy The Most Affordable Short Path Distillation Kit?

Where To Buy The Most Affordable Short Path Distillation Kit?

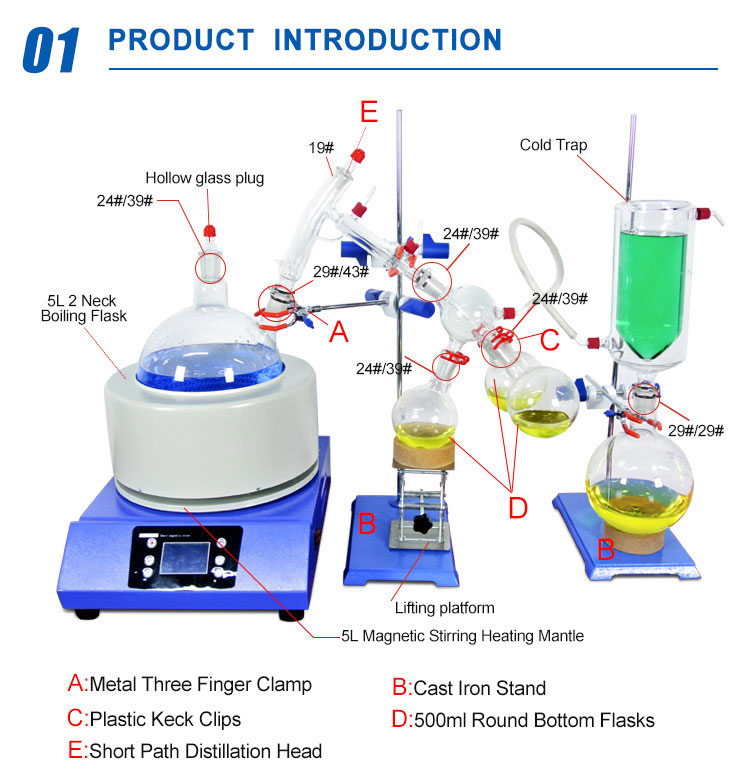

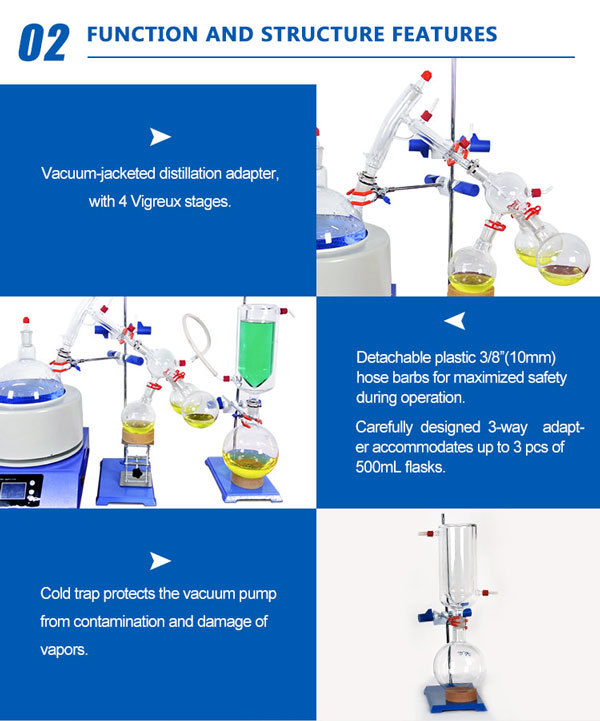

The cdu 1000 distillation process and its counterpart, the cheap short path distillation kit wiped distillation course of, are popular distillation strategies that produce higher taste in their merchandise. Both processes achieve similar results via different means. Short path distillation is the process of separating mixtures, relying on their volatility variations, in a mix of boiling liquid under condensed pressure. As the combination receives warmth, its vapors rise right into a vertical condenser where water is used to cool them down. This approach is often applied with compounds that turn out to be unstable at greater temperatures.

For many years now, experts have been using distillation to separate liquid resolution components via exceptionally selective heating and cooling. To achieve this, a cheap short path distillation kit system is utilized to put under management the divergent properties of the fluid compartments within the mixture. The mixtures will then separate through boiling, evaporation, and condensation.

The methodology may have quite a few applications, however conventionally it’s used to boost the alcohol content material in drinks in addition to water purification for human consumption. Cheap short path distillation kit is a compressed purification approach more suitable for lab purposes where it is important to maintain up minimal instrumentation footprint. This low-pressure technique uses comparatively quick extraction feeds and several flasks to place apart condensate media across paths with only some centimeters.

While the opposite standard strategies want bigger apparatus to achieve the needed purity ranges for specific utility requirements, brief short path distillation solely wants a quantity of components and a small working area to yield as much as 99% distillate purity ranges.

How Short Path Distillation Works

Typically, the term acquires its name given the short distance the distillate covers within the cheap short path distillation kit gear. It travels just some centimeters. A vacuum is used on the setup permitting the distillate to flow from one flask to the next, and in the course of, the sample is separated and purified.

Below is a summary of the steps concerned.

A liquid answer is suspended in evaporating glassware or a flask that connects through a short feed to a chilling unit or condenser.

The evaporating glassware is then put in a heating mantle. Here, the solution’s temperature rises to set boiling factors, allowing distinct compartments of the answer in query to evaporate.

Vapors are actually drawn into the condensing unit through the feed underneath vacuum circumstances. This is the place the separated fuel section layer of the liquid solution cools and converts to a liquid state.

The distillate material is put in numerous glassware relying on their weight. This enables chemists to merge several required elements from one sample.

Benefits of Short Path Distillation

1.Due to the continual feed, producers can persistently make massive quantities of merchandise.This paves the way to greater scalability.

2.The quick path distillation system has a compact design, which makes it best for the extraction of bigger quantities of a number of strains.

3.Most importantly, the brief path distillation gear is very automated and simple to use.

Short Path Distillation Vs Wiped Film Distillation

spd distillation and wiped movie are both single-stage, short path distillation application. Their methods, processing durations, product yield, and cost differ.

Wiped Film Distillation

In the case of wiped movie distillation, the distillation machine produces a film of oil on a hot floor with wiper blades.This allows for liquids with the next viscosity and better boiling points to be distilled and scale back the time spent on a warmth source before evaporation.

Components in the oil evaporate and journey to a close-by condenser and condense on that surface. The wiper is highly engineered to supply a thin film at the evaporator floor that's blended on the surface as nicely. This mixing improves mass switch and the efficiency of the separation.

The heated reservoir holds the winterized decarboxylated oil that feeds the still. The feed is pumped by way of the feed pump and enters the nonetheless underneath excessive vacuum stress.

Conditioned vacuum pressure is supplied by a mix of roughing vacuum pumps and optional turbo molecular pumps. Cold fingers and vacuum condensers are sometimes put in in between the vacuum and the nonetheless to condense volatile molecules in the vacuum in order that a high vacuum gradient exists between the still and the vacuum supply.

As the wipers rotate, the oil is spread onto the evaporator wall. The wipers continue to mix the fluid because it moves down the column.

The operator might want both the residue or the condensate (distillate). So, completely different methods could be run to optimize the restoration of both. Some of those compounds will not condense on the condenser and due to this fact will diffuse via the vacuum and condense on the “cold finger” that's put in just earlier than the vacuum.

When there's an extreme quantity of solvent in the oil to be distilled, a pre-processing step may be required.

Short Path Distillation vs Wiped Film Distillation – Drawbacks and Advantages Compared

The residence time that the oil spends exposed to excessive warmth for brief path distillation is on the order of 10-60 minutes compared to wiped film distillation at 1-3 minutes. This signifies that the terpenes, solvents, and cannabinoids can be separated into completely different fractions using this tools. This is one thing that can not be done on a other equipment.

So, although the duration of the short path distillation application is longer when in comparison with wiped movie, the product yielded shall be of a lot larger high quality. Therefore, more profit could also be generated from a single course of.

Some short path vacuum distillation equipment relies on mechanical means to create a movie for environment friendly evaporation. For instance, a rotary evaporator makes use of a rotating spherical bottom flask to create a film on the glass partitions. A falling film evaporator performs an identical perform that uses gravity to create an evaporative film that runs down the heated column.

Producers might discover a brief path fractional distillation kit to be easier, have a smaller footprint, and the equipment actually comes with a smaller price tag. For these reasons, many producers flip to a brief path as a regular route for distilling hemp extraction solvents.

At ZZKD, we provide a variety of lab devices for many application necessities. Contact us to purchase short path distillation principle tools for your production necessities. We also give advice on equipment choice, on-site and on-line technical help, and free gear testing. Get in contact with us right now to study extra.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.