News

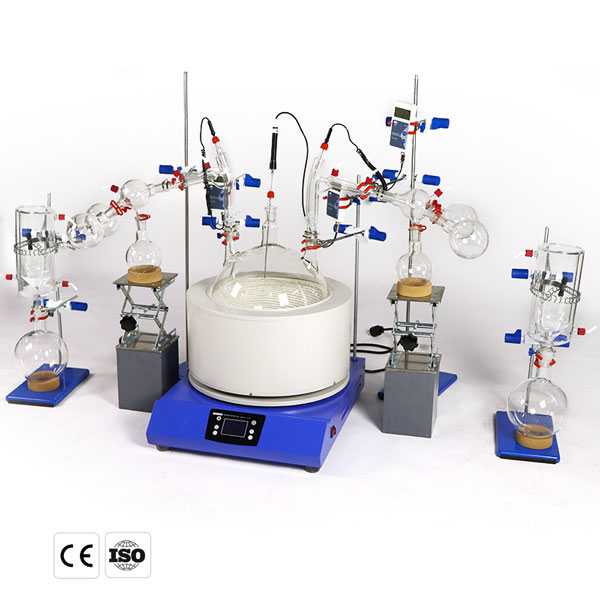

Short Path Distillation Setup

What is short path distillation setup?

Short path distillation setupis a liquid-liquid separation expertise underneath excessive vacuum circumstances. It is completely different from traditional short path distillation setup, which depends on the difference of boiling point, but relies on the difference of the typical molecular free path of various substances. It could be very appropriate for purification. Or separate high-boiling, easily oxidized, heat-sensitive materials. The materials is transferred from the feeding tank to the main evaporator, the jacket is constantly heated, and the movie scraper scrapes the material into an extremely thin, turbulent liquid movie, which is propelled downward in a spiral form. The primary evaporator's built-in condenser offers a short path for the vapor molecules to move from the heating floor to the condensing floor. During the descending process, the lighter components (low boiling level, small molecular weight) in the feed liquid start to vaporize, transfer to the internal condensing floor and liquefy, and circulate into the light component receiving bottle alongside the condensing surface. The heavier (higher boiling level, larger molecular weight) components within the feed liquid can not reach the condensing surface, and can move into the heavy component receiving bottle alongside the heating surface.

Operating Procedures:

1. Install the injector (screw the injector clockwise), first, second, and third receiving bottles, and turn on the cooling water circulation button;

2. Open the wiper rotor and adjust to the speed (not to exceed 400 r/min);

3. Turn on the vacuum pump after the liquid nitrogen reaches the required liquid level (not less than 1/2 of the volume of the condensation column);

4. When the pressure no longer drops, adjust the vacuum pump fine-tuning valve (not lower than 0.5 mbar);

5. After the pressure is adjusted in place, turn the injector valve counterclockwise to adjust the injection speed;

6. During the operation of the equipment, feed liquid can be added at any time through the injector;

7. When the remaining liquid volume in the injector is about 50 ml and no more samples are injected, turn off the vacuum pump and turn back the fine-tuning valve. When the pressure reaches 1000 mbar, wait for 10 minutes. After the pressure is exhausted, turn off the heater and remove the Injector, pour out the remaining sample solution, and replace with absolute ethanol;

8. Replace the first and second receiving bottles, put in empty bottles, unscrew the injector, slowly inject absolute ethanol, and use the residual heat to clean the equipment;

9. After cleaning, turn off the cooling water and the rotor, remove the sampler and receiving bottle for another wash;

10. Turn off the power and clean the countertop.

Features of Short Path Distillation Setup:

1. short path distillation setup has a high vacuum. An essential factor for the short path distillation setup to create a high vacuum system surroundings is that it has an excellent seal, and the interior strain can be reduced to under zero.1Pa.

2. Low short path distillation plant temperature. short path distillation setup separation utilizes the difference in the imply free path of molecules, so the distillation temperature is much decrease than the boiling level of the uncooked material, which solves the issue of heat sensitivity of high value-added chemicals.

3. High separation effectivity. Due to its irreversibility, the short path distillation setup course of can separate materials that can not be separated by strange mini short path distillation kit. This function makes short path distillation setup expertise applicable to the fields of food and medication that require high-purity products.

4. The heating time of the material is brief. The wiper of the short path distillation setup makes the fabric form a uniform movie on the surface of the evaporator, which increases the evaporation space, shortens the short path distillation setup time, reduces the likelihood of the material being decomposed by warmth for a really long time, and makes the separation more efficient and saves time and value.

Technology software:

Short path distillation setup plant is utilized in petrochemical, meals, drugs, flavor and fragrance nice chemical business and different fields, particularly within the separation and purification of natural merchandise and heat-sensitive supplies. For instance, within the extraction of refined fish oil, EPA and DHA in fish oil (this factor known as brain gold, and heaps of infant products have this ingredient) are primarily extracted from marine fish oil. Low oxidation value. In addition, the extraction of pure pigments, pure nutritional vitamins, and natural volatile essential oils all use short path distillation setup. In the petrochemical field, it could be used for the refining of synthetic lubricating base oils, as nicely as for oil analysis, and is used in the deep drawing of vacuum distillate oil. In the pharmaceutical subject, it is used for the purification of medication or intermediates (such because the purification of methyl 4-methoxyacetoacetate, a key intermediate of the anti-HIV-1 drug dolutegravir).

Rules of short path distillation setup:

1. The working temperature is much decrease than the boiling point of the material to treat heat delicate materials, bio-acid fat, high-boiling substances, and materials which might be troublesome to distill have great advantages.

2. The heating time is extraordinarily quick. Ordinary short path distillation setup requires a strategy of a number of hours of warmth, which may be accomplished in a couple of tens of seconds on short path distillation setup, low-carbon and environmentally pleasant, and is conducive to maintaining material exercise.

3. It belongs to the bodily separation course of to maintain the fabric's natural state free from pollution. Widely used in deodorization, decolorization and purification of high value-added supplies.

Short path distillation setup notes:

1. No load isn't suitable for high velocity operation;

2. Keep the pace regulation and the motor dry, as a end result of the lifetime of the electrical box has a great affect on the surrounding humidity and temperature;

3. The floor wire should be well grounded, and the excessive temperature bath should be linked to the open change;

4. There should be electrical shock inside 5 minutes after the power is turned off, because of the discharge of the inverter or capacitor;

5. Please keep away from injury to the glass brought on by hard objects similar to watches and rings when working the instrument;

6. When the glass reactor needs heating, it ought to be steadily heated. Especially when heating at excessive temperature, it is usually beneficial to make use of heat-conducting oil with little harm to the human body.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.