News

Industrial Short Path Distillation System Price

Short stroke scraping process:

Let's take a look at how the short path wiped film distillation process works.

Where other methods use solvents to help the extraction material move or flow through the process, these systems utilize the melting point of the cannabinoid instead.

These compact systems are provided with a feed vessel that feeds the extract into a heated evaporation vessel. Inside this evaporation vessel is a rotating scraper that distributes the extract evenly across the vessel walls. The extraction material only spends a short time on the wall to limit heat exposure and any degradation of the material.

Image courtesy of Root Science

Inside the central evaporation vessel is an internal condenser. This is where the various parts of the extracted material are separated and concentrated.

The close proximity of the condenser to the heated vessel walls provides a shorter path for the extract. Hence the name, short path distillation process. As the wiper system moves the extracted material down through the container, it evaporates to the condenser, which converts it back into a liquid. This liquid is then collected at the bottom, now the distillate.

Heavier materials such as chlorophyll, sugar, salt and wax fractions cannot evaporate from the surface of the evaporation vessel walls, so they pass through the scraper into a separate vessel that is also at the bottom. A separate cooled evaporator captures the terpenes in their own flasks.

Industrial short path distillation process:

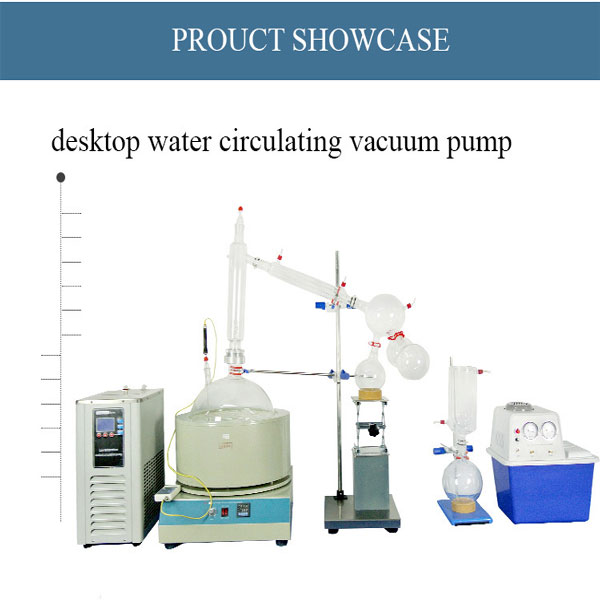

The short path distillation system process employs a setup that uses the same principles, except that there is no wiper system to dispense the extraction material.

Instead, a heated flask is the feed location for the extraction material. Gradually, apply more heat to the extract in the feed bottle. A vacuum was also applied to help draw the vapor into the fractionation tube. The contents from the fractionation tube then enter the condenser tube, where the fractions are split.

Image courtesy of ZZKD.

Benefits of short path distillation system:

Flavor and "experience" are clearly more consumer-centric advantages, but for producers, the advantages of using a short-path distillation process or a short-path wiped film distillation process are even greater. One such production advantage is the so-called "continuous feed", which is ideal for producing large quantities of product with greater consistency over a longer period of time. In the case of other extraction processes using heated beakers, continuous feeding can also provide a greater degree of scalability to your production, which is not a great option for batch mode stills.

High evaporation rates capture more distillate, while relatively low processing temperatures (130-180°C) help not require any solvent to move the extraction material through the process. Most importantly, the system separates cannabis into high concentrations of THC and CBD distillates. In fact, short-path distillation can produce cannabis distillates that are 99% pure. So, for example, if you're trying to make a pure CBD product, using the short-path distillation process is one of the best methods you can use.

The compact design of industrial short path distillation makes it ideal for operations that require the extraction of large numbers of diverse strains.

Finally, these machines are easy to use and largely automated.

Cost of Industrial short path distillation:

Now you know how these very similar distillation processes work and how they can benefit your production.

But how much does the 20l short path distillation kit cost? Zhengzhou Keda Machinery Equipment Co., Ltd. is an enterprise integrating production and trade, providing experimental and production equipment. There are several places where cdu 1000 distillation can be purchased, and the price of these equipment may vary depending on the kind of capacity they have.

You can expect basic turnkey short-path systems to start at less than $3,000 and can go well over $10,000, depending on capacity and features.

Wiped film evaporators can range from $5,000 to $40,000, depending on capacity and functionality. If you have a large business or are looking to significantly scale up your production, then investing in wiped film evaporators is the right choice as they can handle larger volumes of product. Of course, this is only an approximation, please contact us for the specific price.

Isolation and full spectrum:

Using a short-path distillation or wiped-film distillation process results in a pure isolate—whether it’s THC, CBD, or any other cannabinoid or terpenes you might choose to distill.

Isolates are the purest and most potent form of compounds, and they have some benefits, such as being completely odorless. For example, it's great if you're using these compounds in food or beverages because it doesn't change the taste in any way.

However, a growing body of scientific research has found that full-spectrum extracts offer many benefits over isolates. The myriad of compounds found in cannabis work together to form the so-called entourage effect, which enhances the effectiveness of the medicinal properties.

Therefore, you may wish to extract the pure isolate resulting from the short path distillation process and use reverse chromatography which produces a full spectrum extract. This is especially useful for creating highly potent CBD products, for example, (short path distillation kit thc) because the final product still has no trace of THC, but still contains many of the other beneficial compounds found in cannabis.

The beauty of using industrial short path distillation is that you can isolate each specific compound and then combine them into unique mixtures that produce highly specific results. When you use a precise technique like the short path distillation system, the possibilities are endless.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.