News

Advantages and application of short path distillation

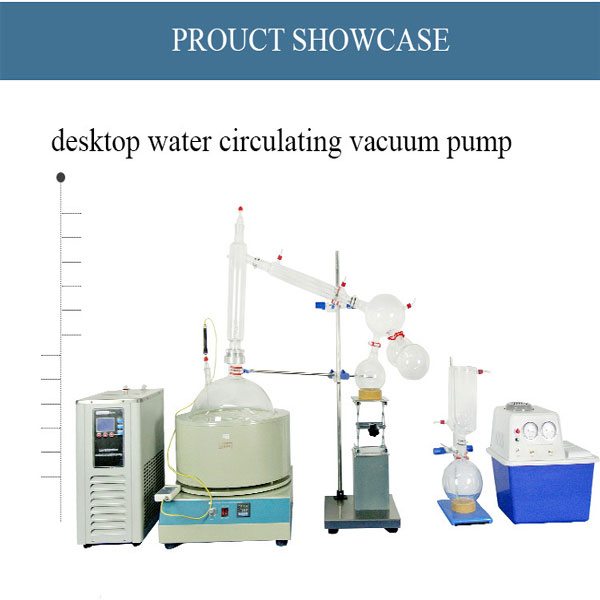

Product description:

According to the Royal Society of Chemistry, cdu 1000 distillation is "A methodology of separating mixtures based mostly on differences of their volatilities in a boiling liquid combination underneath reduced stress". Because it uses a lower boiling temperature, short-path distillation equipment is especially helpful for separating compounds which are unstable at higher temperatures. It's also useful for purifying small quantities of compound.

Spd distillation includes using a heated flask to progressively increase the temperature of the extraction material that's fed into it. As the combination heats up, its vapors rise into a fractioning tubing with the assist of a vacuum. The vapors journey a brief distance—often just a few centimeters—into the tubing earlier than being condensed, which is where the time period "short-path" comes from. Because the vapors only journey a short distance, minimal quantities of the compound are wasted on the sides of the tools. After passing via the fractioning tubing, the vapors enter the condensing tube. Here, they are cooled by water in a recirculating chiller, which permits for his or her condensation. Depending on the load of every fraction, they will be separated all through the condensing tube into different receiving flasks.

Advantages of short-path distillation

Better for temperature-sensitive compounds: The use of a vacuum reduces pressure, so the distilling temperature used for short-path distillation could be much decrease than the compound’s boiling temperature. Short-path distillation doesn’t require you to topic compounds to high temperatures for long durations, which are sometimes necessary when distilling at normal stress. Since the method can take place at lower temperatures, this technique is especially beneficial for compounds that become unstable at high temperatures or have a excessive boiling point.

Prevents wasted compound: Short-path distillation only requires a liquid to travel a brief distance, so much less compound is misplaced in the gear. It's a more-efficient methodology that reduces material waste.

Good for purifying small amounts of compound: Short-path distillation is the perfect methodology to distill small quantities. This is as a outcome of the liquid travels throughout a shorter floor space and fewer compound is retained on the tools.

Ease of use: One of the main advantages of short-path distillation is its ease of use. Most standard distillation techniques require large apparatuses to succeed in their desired purity ranges. The equipment used for short-path distillation, however, can obtain high distillate purity ranges with out the necessity for cumbersome, cumbersome equipment. The technique is right for these with smaller working areas.

Quick heating process: While different typical evaporation apparatuses sometimes take hours to complete a separation, short-path distillation might solely take a quantity of seconds.

Application of quick path distillation:

short path distillation principle is widely utilized in numerous features of the nationwide financial system, particularly for the separation of high boiling point and heat delicate and easy oxide supplies. The applications can be concluded as follows:

●Distillation and concentration. Short-path distillation strategies are utilized in pure and artificial vitamins, wool fatty acids, lanolin, palm oil, rice bran oil, fish oil and cod liver oil, pure plant leaf root extract (such as capsanthin, lycopene, pyrethrin, The utility of lecithin, b-carotene, lively components of conventional Chinese medicine, and so forth.

●Removal of solvent. With the development of latest domestic and worldwide requirements and the continual enchancment of people’s dwelling requirements, the restrictions on solvent residues in chemical raw supplies and their products closely associated to human beings corresponding to food, medication, cosmetics and constructing supplies have gotten increasingly strict. Traditional distillation methods have been unable to fulfill the wants of the market, and this kind of process usually follows the extraction technique as the final quality assurance system for green merchandise.

●Decolorization and deodorization. Typical examples are: natural intermediates, lactic acid, fatty acids and derivatives thereof, APG, epoxy resins, epoxidised oils, vegetable waxes, silicone oils, brake fluids, vacuum pump oils, lubricating oils, paraffin oils, and so forth.

●Preparation/production of high-boiling process supplies and willpower of boiling range. Short-path distillation know-how can obtain distillation separation in a vacuum of 0.001 mbar and a heating time of lower than 1 minute, so it's undoubtedly the popular know-how for distillation separation for these heat-sensitive high-boiling substances.

If you want tools to complete your lab,Lab Equipment Manufacturer can help. We can Manufacture a wide variety of evaporation equipment—from short-path distillation kits to 50-liter rotary evaporators. For extra info regarding our equipment, contact us right now.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.