News

Short-path distillation system, efficient distillation equipment | ZZKD

|

|

|

|

SPD-2L Short-path Distillation |

SPD-5L Short-path Distillation |

SPD-10L Short-path Distillation |

SPD-20L Short-path Distillation |

What is short-path distillation?

Short-path distillation is a compact purification method that is ideal for laboratory applications that require minimal instrument footprint. This low pressure technique uses multiple flasks and a relatively short extraction feed to separate the condensing medium over a few centimeters. Conventional distillation methods typically require larger equipment to achieve the level of purity required for application specific requirements. At the same time, short-path distillation can achieve up to 99% distillate purity levels using multiple components in a small workspace.

Commonly used in food, pharmaceuticals, fine chemicals, electronic materials, plastics engineering and polymers (such as polyols, fatty acids, polyphenols, polyurethanes, epoxies, lactic acid, monoglycerides, flavors, heavy oils and paraffin oils) Separation and purification and other fields.

Commonly used in food, pharmaceuticals, fine chemicals, electronic materials, plastics engineering and polymers (such as polyols, fatty acids, polyphenols, polyurethanes, epoxies, lactic acid, monoglycerides, flavors, heavy oils and paraffin oils) Separation and purification and other fields.

How does short-path distillation work?

The short-path distillation equipment is to heat-distill the reactor containing the material through an electric heating mantle, and then collect the concentrated materials by a cooling pipe connected with a low-temperature cooling circulation pump. For distilled materials that cannot be reached under normal pressure, we usually use a vacuum pump to vacuum the entire equipment so that the entire distillation system is under negative pressure to reach the desired temperature to distill the material.

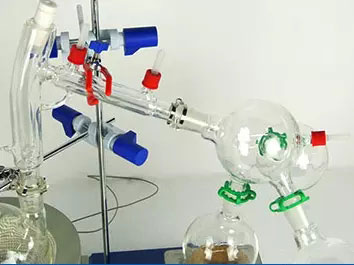

Detail Images

|

Vacuum jacketed distillation adapter, with 4 vigreux stages. |

|

|

Carefully designed 3-way adapter accommodates up to 3 pcs of 500ml flasks. |

|

Cold trap protect the vacuum pump from contamination and damage of vapors. |

|

What are the characteristics of short-path distillation?

1. The product is made of high quality borosilicate material.

2. The glass parts are connected by a matte port, which is easy to operate and has good sealing performance.

3. The structural size can be customized according to the special needs of customers.

4. High-precision transmission and mechanical seal design to ensure long-term smooth operation of equipment

5. The evaporation cylinder is integrally formed without intermediate flange connection.

6. The surface of the cylinder has a high surface finish and is not easy to stick.

7. Unique liquid distributor and splash-proof device design to ensure product quality

How to maintain short-path distillation equipment?

1. Check the instrument carefully before use. Whether the glass bottle is damaged or not, and whether the interfaces are consistent, pay attention to light handling.

2. When making any repairs or inspections on the short-path distillation, be sure to cut off the power supply.

3, the electrical part must not enter the water, it is strictly prohibited to get wet.

4. Wipe each interface with a soft cloth (can be replaced with a napkin) and apply a small amount of vacuum grease. The vacuum grease must be covered after use to prevent the entry of lime sand.

5. The interfaces of the distillation equipment should not be tightened too tightly. It should be loosened regularly to avoid the long-term tight lock and cause the connector to bite.

6. Turn on the power switch first, then let the machine run from slow to fast. When the machine stops, stop the machine and turn off the switch

7, must purchase the original authentic accessories, free use of other accessories can cause fatal damage to the machine.

8. Every time you use it, you must use a soft cloth to clean all kinds of oil traces left on the surface of the machine, stains, solvent remaining, and keep it clean.

2L Short Path Distillation Specification

| Model | Parts name | Parts number |

| 2L short path distillation | 2000 ml Digital Heating Mantle | 1 |

| 2000 ml 2 Neck Boiling Flask | 1 | |

| Short Path Distillation Head | 1 | |

| Cow Receiver | 1 | |

| 500 ml Round Bottom Flasks | 3 | |

| Plastic Keck Clips | 7 | |

| Cast Iron Stand | 1 | |

| Metal Three Finger Clamp | 1 |

5L Short Path Distillation Specification

| Model | Parts name | Parts number |

| 5L short path distillation | 5000 ml Digital Heating Mantle | 1 |

| 5000 ml 2 Neck Boiling Flask | 1 | |

| Short Path Distillation Head | 1 | |

| Cow Receiver | 1 | |

| 500 ml Round Bottom Flasks | 3 | |

| Plastic Keck Clips | 7 | |

| Cast Iron Stand | 2 | |

| Metal Three Finger Clamp | 1 | |

| Cold trap | 1 | |

| PTFE magnetic stirring bar | 1 | |

| Lifting platform | 1 | |

| backing ring | 1 |

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.