News

What should I pay attention to when using short-path distillation?

The short-path distillation system is a distillation apparatus that uses high temperature for distillation because of its small size, high recovery rate, and simple operation. It is loved by manufacturers of CBD oils and essential oils.

What should I pay attention to before using?

1. Check the equipment before using the distillation equipment to confirm that the equipment is in good condition.

The main part of the short-distance distillation and some of the parts are made of excellent glass and are fragile items. Therefore, you must confirm the integrity of the equipment before use to avoid injury during the reaction.

2. Confirm the integrity of the entire system of short-path distillation.

Some reaction experiments require the use of other equipment, such as vacuum pumps, low temperature coolant circulation pumps, low temperature constant temperature reaction baths and other equipment. Be sure to confirm the integrity of the entire operating system, avoid stopping the reaction in the middle, resulting in waste of material.

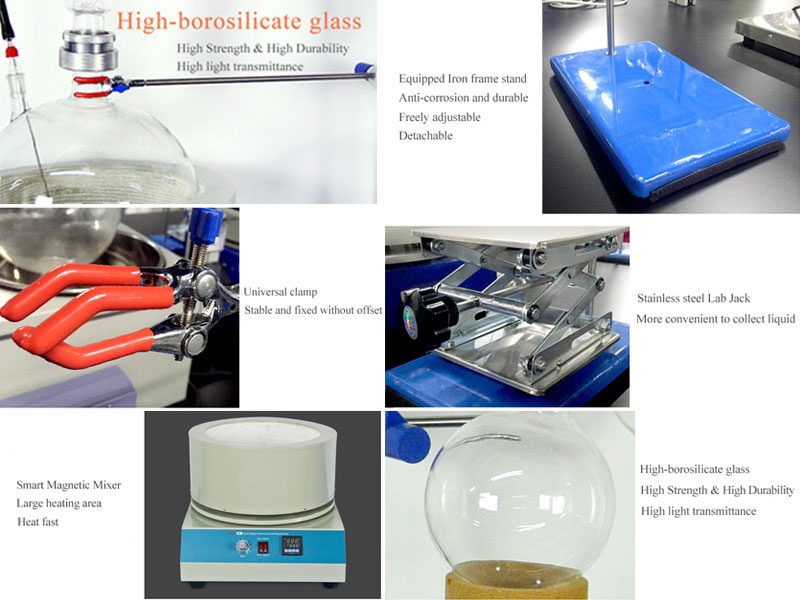

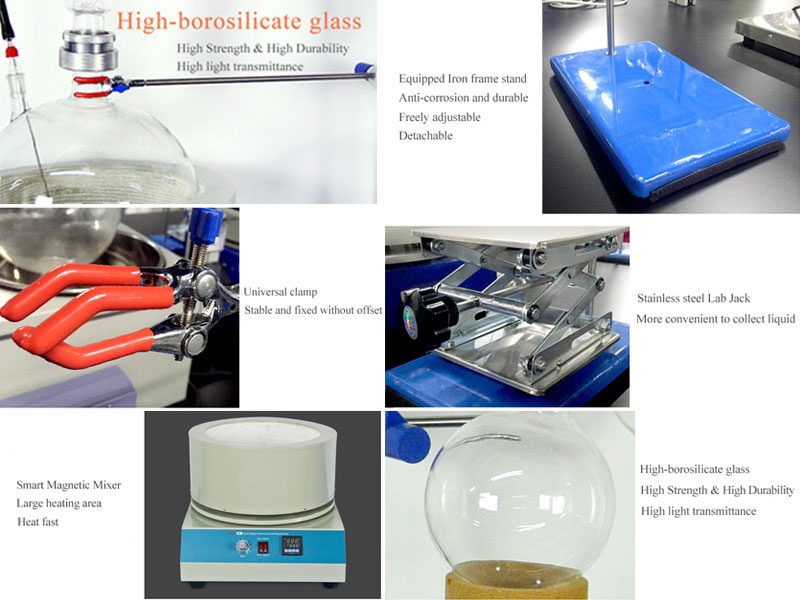

Laboratory short-path distillation features

1. The product is made of high quality borosilicate (G3.3)

2. The glass parts are connected by a matte port, which is easy to operate and has good sealing performance.

3. The structural size can be customized according to the special needs of customers.

4. Vacuum degree: 0.098Mpa

What should you pay attention to when using short-path distillation equipment?

1. Check if the inlet and outlet valves of the cooling water are normally open and the pressure is within the normal range.

2. Check if the inlet and outlet valves of the cooling water of each component are in the open state.

3. The equipment is heated by hot oil. The surface temperature of the external heating body is high. Do not touch it with your hands to avoid burns.

4. Check if the ethanol in the cryostat is sufficient.

5. Pay attention to whether the liquid nitrogen in the liquid nitrogen tank is sufficient.

6. Check if the connection between the cold well and the equipment is closed.

7. There may still be electric shock within 5 minutes after the power is turned off, due to the discharge of the inverter or capacitor;

8. Please avoid damage to the glass caused by hard objects such as watches and rings when operating the instrument;

Short-path distillation equipment maintenance

1. Check the instrument carefully before use. Whether the glass bottle is damaged or not, and whether the interfaces are consistent, pay attention to light handling.

2. When making any repairs or inspections on the short-path distillation, be sure to cut off the power supply.

3, the electrical part must not enter the water, it is strictly prohibited to get wet.

4. Wipe each interface with a soft cloth (can be replaced with a napkin) and apply a small amount of vacuum grease. The vacuum grease must be covered after use to prevent the entry of lime sand.

5. The interfaces of the distillation equipment should not be tightened too tightly. It should be loosened regularly to avoid the long-term tight lock and cause the connector to bite.

6. Turn on the power switch first, then let the machine run from slow to fast. When the machine stops, stop the machine and turn off the switch

7, must purchase the original authentic accessories, free use of other accessories can cause fatal damage to the machine.

8. Every time you use it, you must use a soft cloth to clean all kinds of oil traces left on the surface of the machine, stains, solvent remaining, and keep it clean.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.