News

Important equipment for short-path distillation system|rotary vane vacuum pump

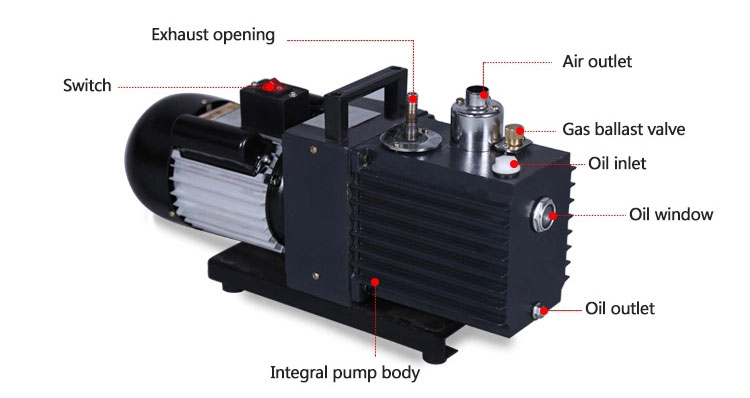

The rotary vane vacuum pump is one of the basic equipments to exhaust a sealed vessel. It can be used either independently as main and can also be served as forepump for booster pump diffusion pump and molecular pump or as holding pump for a vacuum system and as a pre-pumping for different kinds of the pumps. So it can be applied in electro-vacuum industries, vacuum flask manufacturing, vacuum welding and as an accessory to those fine gauges or meters where vacuum is required. It is more suitable for laboratory use because of its small size, less weight and quiet operation.

Rotary vane vacuum pump

Rotary vane vacuum pump is a step

1. Check the oil level to prime the oil to the center of the oil mark when the pump is stopped. Too low to the exhaust valve can not act as an oil seal, affecting the degree of vacuum. Too high may cause fuel injection when the atmosphere is started. When operating, the oil level is raised, which is normal. The oil is supplied with a specified grade of clean vacuum pump oil from the oil filler hole. After refueling, the screw plug should be screwed on. The oil should be filtered to prevent debris from entering and clogging the oil holes.

2. The rotary vane vacuum pump can be started once in the atmosphere or under any vacuum. If the pump port is connected to a solenoid valve, it should be operated simultaneously with the pump.

3. When the ambient temperature is too high, the temperature of the oil rises, the viscosity decreases, and the saturated vapor pressure increases, which causes the ultimate vacuum to decrease, especially the total pressure measured by a thermocouple. The ultimate vacuum can be improved by enhancing ventilation or improving pump performance.

4. Check the ultimate vacuum of the rotary vane vacuum pump according to the compressed mercury vacuum gauge. If the pre-extraction check is completed, the pump temperature will be stable, the pump port and the meter will be directly connected, and the ultimate vacuum will be reached within 30 minutes of operation. The value measured by the total pressure gauge is related to the pump oil and vacuum gauge, and the regulation error. Sometimes the error can be very large and can only be used as a reference.

5. If the relative humidity is high, or the pumped gas contains more condensable steam, after opening the pumped container, the gas ballast valve should be opened, and the gas ballast valve should be closed after 20 to 40 minutes of operation. Before stopping the pump, the open air valve can be unloaded for 30 minutes to extend the life of the pump oil.

6. Oil selection for rotary vane vacuum pump: The viscosity of the pump oil affects the starting power and the ultimate vacuum of the pump. When the viscosity is high, the vacuum is favorable, and the starting power is larger. The saturated vapor pressure of the oil at the pump temperature will affect the ultimate pressure of the pump. The lower the better. The viscosity of high-speed vacuum pump oil and 3# diffusion pump oil is larger than that of No. 1 vacuum pump oil, and the saturated vapor pressure is lower than that of No. 1 vacuum pump oil, but the price of 3# diffusion pump oil is higher. The specific oil selected can be selected according to the above description combined with the specific use requirements.

a. Under normal circumstances, if you want a total pressure of 6X10-2 Pa or more, apply Shanghai high-speed vacuum pump oil. The small pump below 4 liters/second can also be replaced by the No. 1 vacuum oil pump. The direct pump of 8 liters/second or more can be replaced by the 3# diffusion pump oil.

b. If the vacuum degree is not high, and the oil pollution is frequently replaced, the vacuum pump oil supply is difficult, and the 50th mechanical oil can be used instead.

c. If the ambient temperature is low, the starting is difficult, the ultimate vacuum requirement is not high. Vacuum pump oil or mechanical oil with a slightly lower viscosity may be used.

Rotary vane vacuum pumps are an important device in the entire short-path distillation system.

The laboratory short-path distillation unit is a distillation technique involving the distillate traveling a short distance, usually only a few centimeters, usually under reduced pressure. The rotary vane vacuum pump can solve the problem of working under this negative pressure.

Most of the short-path distillation equipment is made of glass material, and it is necessary to avoid damage to the equipment during the use.

Note on short-path distillation when used:

1. Check if the inlet and outlet valves of the cooling water are normally open and the pressure is within the normal range.

2. Check if the inlet and outlet valves of the cooling water of each component are in the open state.

3. The equipment is heated by hot oil. The surface temperature of the external heating body is high. Do not touch it with your hands to avoid burns.

4. Check if the ethanol in the cryostat is sufficient.

5. Pay attention to whether the liquid nitrogen in the liquid nitrogen tank is sufficient.

6. Check if the connection between the cold well and the equipment is closed.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.