News

2xz rotary vane vacuum pump - vacuum equipment

2XZ series rotary vane vacuum pumps are the most widely used vacuum pumps for the short-path distillation kit. They have a wide range of uses.

2XZ rotary vane vacuum pump uses and scope of application:

Due to the high development of modern science and technology, the application of 2XZ rotary vane vacuum pumps has been applied in various scientific fields and various enterprises and institutions, and its main manifestations are:

1. It can be used for scientific research, production and teaching of metallurgical, chemical, light industry, petroleum, medical, pharmaceutical, printing and dyeing, electrical appliances, vacuum, semiconductors, food, atomic energy, textile and other scientific research institutions, colleges and universities, industrial and mining enterprises.

2. Since the 2XZ rotary vane vacuum pump is made of ferrous metal and is relatively precise, the entire pump work is associated with oil, so it is not suitable for removing oxygen-rich, toxic, explosive Various gases that etch ferrous metals and chemically act on vacuum oil are not suitable for use as compressors and pumps. If there is a pump with a gas ballast device, a certain amount of condensable vapor can be removed.

3. The 2XZ rotary vane vacuum pump can be used to directly obtain vacuum operation with a vacuum degree below 10-3 Torr, and cooperate with other vacuum equipment to obtain a vacuum effect with a vacuum degree above 10-3 Torr.

4. The 2XZ rotary vane vacuum pump is generally used in an environment where the temperature is not lower than 5 ° C and the relative temperature is not higher than 90%.

It can be equipped with a vacuum booster pump according to the user's situation. The pump can be used as a foreline pump. As the pumping power of the booster pump is strengthened and the foreline pump is continuously removed, the equipment can obtain a higher vacuum.

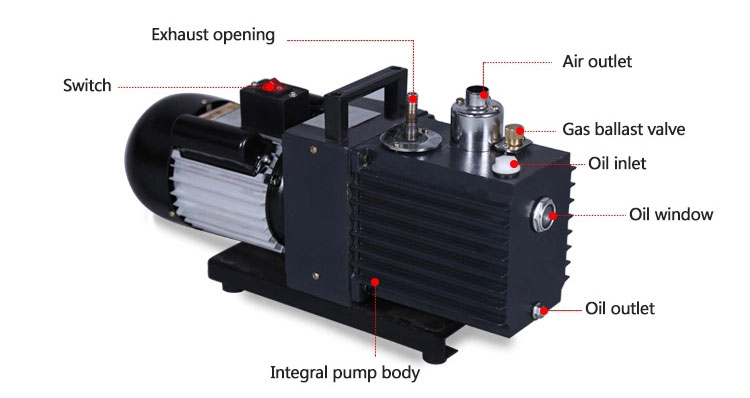

2XZ Rotary Vane Vacuum Pump Overview:

2XZ rotary vane vacuum pump is a two-stage direct-connected structure. Its working performance consists of a high-pressure stage and low-pressure stage. Its suction port is connected to a vacuum device. During operation, a large amount of gas is sucked in and discharged from the container. When the equipment obtains a vacuum, the high-pressure stage exhaust valve is closed, and the gas at the high-pressure stage inlet will be transferred to the second stage, and a certain vacuum can be obtained through the second stage suction and discharge vacuum equipment. 2XZ type rotary vane vacuum pump technology The parameter is 6 × 10-2Pa, the pump and the motor are connected to the shaft, high speed, small size, compact structure, convenient fluidity work, can be used for electric vacuum device manufacturing, thermos bottle manufacturing, vacuum welding, printing, plastic suction, refrigeration equipment Repairs and instrumentation. Because it has the advantages of small size, lightweight, and low operating sound, it is more suitable for laboratory use.

Features of 2XZ rotary vane vacuum pump:

2XZ type rotary vane vacuum pump has the advantages of small size, lightweight, low noise and convenient starting. In addition, there are measures to prevent oil return (2XZ-8) and measures to prevent the oil seal from leaking oil to contaminate the site.

1, 2XZ rotary vane vacuum pump is the basic equipment to obtain vacuum, it can be used alone, can also be used as a fore pump and pre-pump for various high vacuum systems.

2. The air inlet of the 2XZ rotary vane vacuum pump is continuously open to the atmosphere and cannot exceed three minutes.

3. The pump is not suitable for the extraction of gases that are corrosive to metals and chemically react with the pump oil and contain particulate dust. Gases that contain too much oxygen and are explosive.

4. The pump may be used as a compression pump or a delivery pump.

5. Working environment of 2XZ rotary vane vacuum pump: in the temperature range of 5 ℃ -40 ℃, the relative temperature is not more than 90%, and the inlet pressure is less than 1333Pa to allow long-term continuous operation.

6. When connecting the power supply, connect the wires according to the specifications on the motor label. Pay attention to the direction of rotation of the motor is consistent with the direction of the arrow on the support.

7. The diameter of the pipeline to be continuously pumped should not be less than the diameter of the air inlet of the pump, and the pipeline should be short and the number of elbows should be small. At the same time, pay attention to the leakage of the pipeline.

8. Focus on checking the oil level before each start. It is advisable to fill the oil to a height of 4/5 of the diameter of the oil glass when the pump is stopped.

9. The pump oil is clean SY1634-701 vacuum pump oil.

10. The 2XZ rotary vane vacuum pump can be started at one time under the atmosphere or any vacuum degree. If the XZ-1 single-stage pump is difficult to start, you can remove the intake pipe plug cap to start and then put it

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.