News

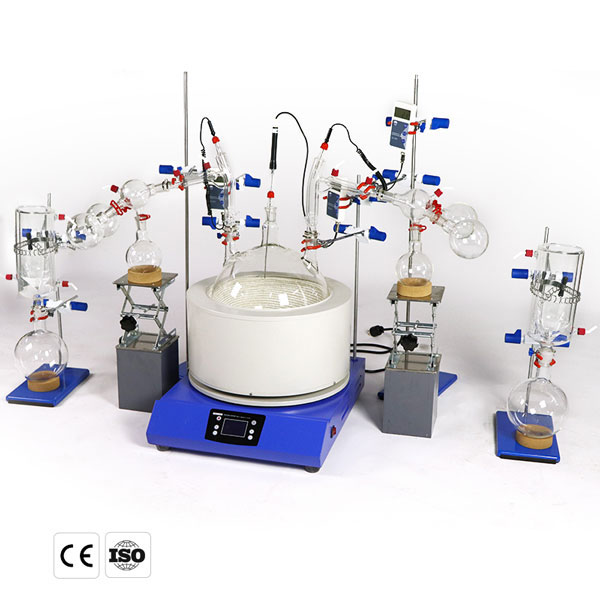

Short Path Distillation Organic Chemistry

Short path distillation organic chemistry is a general heating instrument in the laboratory. The driving force for steam flow is the pressure difference between the boiling film and the condensing surface, and a small pressure drop will cause the flow of steam. Operating at 1mbar and requiring a shorter distance between the boiling surface and the condensing surface, the distiller made according to this principle is called a short-path distiller. Short path distillation organic chemistry has the characteristics of fast heating, easy operation and firmness. It can replace conventional falling film evaporators for distillation, purification, concentration, and decolorization of petrochemical and chemical products; it is especially suitable for distillation and refining of heat-sensitive and easily oxidized chemical industrial products; it can also be used for distillation and separation of high-boiling point products.

Precautions:

1. Check whether the cooling water inlet and outlet valves are normally opened and whether the pressure is normal.

2. Check whether the inlet and outlet valves of the cooling water of each component are open.

3. The equipment is heated by hot oil, and the temperature is high. Do not touch it with your hands to avoid burns.

4. Check whether there is enough ethanol in the low temperature constant temperature tank.

5. Pay attention to whether the liquid nitrogen in the liquid nitrogen tank is sufficient

6. Check whether the connection between the cold well and the short path distillation organic chemistry is airtight.

Features of short path distillation organic chemistry:

1. The fractionation process of short-path distillation is a physical process, so it can well protect the separated substances from pollution.

2. Short-path distillation provides a suitable separation method for materials with high boiling point, heat-sensitive and easily oxidized materials. Because the short-path distillation material has a short residence time and operates at a temperature much lower than the boiling point of the material

3. Short-path distillation can selectively distill out the target product and remove other impurities, and more than three or four substances can be separated at the same time through multi-stage separation;

4. The short-path distillation operation vacuum can reach 1-5Pa, which is difficult to achieve with other evaporative distillation equipment.

5. The distilled liquid film is thin, the heat transfer efficiency is high, and the film thickness is less than 0.5mm.

6. The degree of separation is higher. Molecular distillation can separate substances that are not easy to separate.

7. The short distance between the heating and cooling surfaces causes minimal thermal stress on the distilled product.

8. At present, we have 2L, 5L, 10L, and 20L models to choose from, double-sided short-path stills are optional, insulation clothing, and insulation strips are optional.

9. The electric heating mantle is used for distillation, the heating area is large, the heating is uniform and fast, and the maximum temperature can reach 380°C.

10. The scraper system is made of PTFE material and SS316L stainless steel material, which has the function of anti-corrosion.

Cleaning of short path distillation organic chemistry

Because most of the distillation parts of short path distillation organic chemistry are glassware. Glasses used in short path distillation organic chemistry are particularly susceptible to baked-on and aggregated contaminants during long distillations

Stains, combined with the construction of glassware, are very difficult to clean. Regarding the cleaning of short path distillation organic chemistry, there are several traditional methods.

First, the traditional method of cleaning glassware:

Using aggressive chemicals for cleaning has three disadvantages:

1. When corrosive chemicals are used, the residence time of the glass may be very long in order to break through the plasticized layer, thereby delaying the return to service.

2. Regulations may provide that internal operating procedures should be adjusted if corrosive chemicals create hazardous working conditions.

3. These chemicals are hazardous to handle in high concentrations and need to be handled safely and correctly.

Second, the principle of ultrasonic cleaning:

The ultrasonic cleaning process occurs so quickly that the cleaning process does not cause any damage to the cleaned parts, which is ideal for glassware and other equipment used in laboratory short-path distillation.

The cleaning procedure is as follows:

1. Add water and a wetting agent such as dish detergent to the ultrasonic cleaner tank fill line.

2. Fill the flask with enough cleaning solution to cover the contamination.

3. Put the bottom of the flask into water without soaking. Trays and clamps are available to support flasks during cleaning cycles.

4. Activate the ultrasound. Cavitation passes through the flask wall and acts on the contaminants

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.