News

Short Path Distillation Equipment

The traditional distillation method in the biochemical industry is being replaced more and more by short path distillation equipment, because compared with the traditional distillation method, short path distillation equipment has two absolute advantages: on the one hand, the distillation unit The absolute pressure is reduced to 0.001mbar, which can greatly reduce the boiling point of the substance to be distilled; on the other hand, the specially designed distillation unit structure shortens the heating time of the substance to less than 1min. The reduction of the distillation temperature and the shortening of the heating time make the short path distillation equipment, for those high-boiling heat-sensitive substances that need to be separated by distillation, can avoid their thermal decomposition to the greatest extent so as to maintain the original chemical and biological active structure of the substance.

Short path distillation equipment

In simple distillation, when substances are heated to their normal boiling point, the highly volatile components are volatilized in gaseous form, and the gas is then introduced onto a cooling surface to condense. Thus highly volatile components are enriched in the condensate while low volatile components remain in the distillation unit. A relatively simple traditional distillation method is batch operation. In order to lower the evaporation temperature, a vacuum pump must be used after the condenser, however the achievable vacuum in the distillation unit is extremely limited for the following reasons. First of all, the vapor pressure of the liquid itself, which exists in large quantities in the distillation unit, directly hinders the reduction of its internal pressure. Second, the pipeline between the condenser and the distillation unit is inevitable, and this pipeline effect greatly limits the working efficiency of the vacuum pump, thus hindering the further drop of the pressure in the distillation unit.

The use of short path distillation equipment can eliminate the pipeline effect, because the short-path evaporator is a built-in condenser structure, and the molecules evaporated on the heating surface only need to go through a short distance to reach the condensation surface (when the heating surface and the condensation surface When the distance between them is less than the mean free path of the molecules, it is called molecular distillation). This special design makes it possible to achieve high vacuum in the distillation unit. But the lower the pressure, the lower the density of vapor allowed in the distillation unit, and thus the lower the distillation rate. This means that the vacuum degree of industrialized short path distillation equipment cannot be increased without limit.

Short Path Distillation Technology

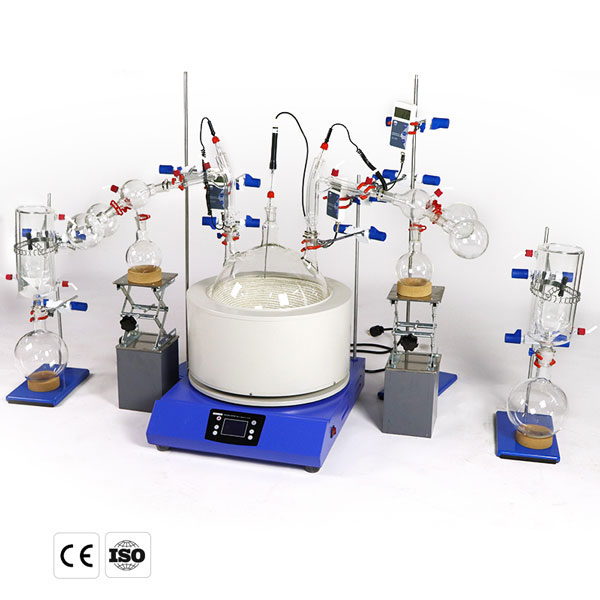

The short path distillation equipment generally consists of a vertical jacketed cylindrical distillation unit, an internal condenser and a film forming system. The operation process of short path distillation equipment can be briefly summarized as follows:

(1) The material to be distilled is continuously injected into a high-speed rotating disc. Under the action of centrifugal force, the material is distributed to the inner surface of the distillation unit.

(2) Use heat medium (electricity, steam or hot oil) to heat the distillation unit evenly and continuously.

(3) The injected raw material is evenly distributed on the inner surface of the cylinder by the film forming system and moves downward under the action of gravity.

(4) At a certain temperature and vacuum, some components evaporate on the heated surface, and the composition of the components in the liquid phase will change at the same time.

(5) The substance evaporated into gas is converted into liquid by built-in condenser for collection.

Features of Short path distillation equipment:

The distance between the evaporation surface and the condensation surface is very short; the vacuum degree of 0.001 mbar can be realized in the distillation unit, which greatly reduces the evaporation temperature of the substance;

●The residence time of the substance at high temperature is less than 1 min;

●For some short path distillation equipment, since the film-forming system is not in contact with the evaporation surface, the wear of the film-forming system is very small;

The heating temperature is mostly 250℃, 350℃, 450℃

● The main materials of short path distillation equipment are borosilicate glass, stainless steel or other alloy materials required by users, such as Duplex - Steel, Hastelloy, titanium steel and other corrosion-resistant materials.

In addition to the distillation unit, a complete set of short-path distillation equipment in industrial production should also include the following configurations: feed unit, heating and condensation unit, vacuum system, process control system, middle distillate and product collection unit, etc.

.

Application

International short path distillation sop achieved rapid development in the early 1960s, and its main application field began in the daily chemical industry, which is closely related to people's lives. The following is the current international market application of short path distillation sop.

Biochemical industry

Alcohol, hexylene glycol esters, pesticides, hydrocarbon compounds, herbicides, silicone oil, paraffin, brake fluid, vacuum pump oil, lubricating oil.

Food industry

Glyceryl Monostearate, Diglyceride, Palm Oil, Fertility Powder, Fish Oil and Cod Liver Oil, Rice Bran Oil, Fatty Acids and Derivatives, Fatty Acids

Di_mer, fatty acid ester, seed oil, butter, lactic acid, vegetable wax

Pharmaceutical industry

Amino acid esters, vitamin E, glucose derivatives, indole compounds, unsaturated terpenoids, natural and synthetic vitamins, beta-carotene.

Cosmetics industry

Wool fatty acid, wool alcohol, extract of natural plant leaf neck root

Plastics industry

Epoxy resin, epoxy oil, polyurethane, resin, plasticizer, stabilizer, isocyanate, acrylate.

Mineral oil industry

Crude oil, lubricating oil, paraffin oil, long and short chain asphalt, tar, waste oil recovery, etc.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.