News

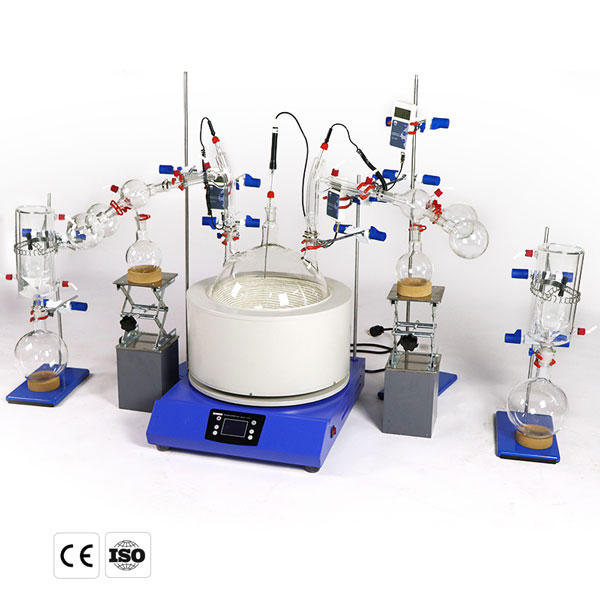

Short Path Distillation Apparatus

The short path distillation apparatus is a distillation method equipment operated under high vacuum, which is mainly used for effective separation and purification of temperature-sensitive and unstable compounds. The control system in the equipment is mainly used to reduce the boiling point of its materials, short The special structure of the path distillation apparatus can very effectively control the rapid and continuous flow of its materials, mainly in the form of thin films that are heated through the surface of the equipment.

Short path distillation apparatus process:

1. Diffusion of molecules from the main body of the liquid phase to the evaporation surface: Usually, the diffusion speed in the liquid phase is the main factor controlling the molecular distillation speed, so the thickness of the liquid layer should be reduced as much as possible and the flow of the liquid layer should be strengthened.

2. Free evaporation of molecules on the surface of the liquid layer: the evaporation rate increases with the increase of temperature, but the separation factor sometimes decreases with the increase of temperature, so the thermal stability of the processed substance should be taken as the premise , choose an economical and reasonable distillation temperature.

3. Molecules flying from the evaporating surface to the condensing surface: During the process of flying from the evaporating surface to the condensing surface, the vapor molecules may collide with each other or collide with the remaining air molecules between the two surfaces. Because evaporated molecules are much heavier than air molecules, and most of them have the same direction of motion, their own collisions have little effect on the direction of flight and evaporation speed. The residual gas molecules are in a chaotic thermal motion state between the two sides, so the number of residual gas molecules is the main factor affecting the flying direction and evaporation speed.

4. Molecules condense on the condensing surface: as long as there is a sufficient temperature difference between the hot and cold sides (generally 70~100°C), and the form of the condensing surface is reasonable and smooth, the condensation step can be completed in an instant.

Short path distillation apparatus features:

Short residence time: The function of the film wiper makes the residence time of the liquid film on the heating surface extremely short.

Low distillation temperature: Since the condenser is directly opposite the heating surface, the pressure difference is reduced, so it has a very high degree of vacuum, and the material can be distilled at an extremely low temperature even without reaching the boiling point.

Sticky matter and solid matter in the product: the deep immersion of the scraper, relying on a considerable edge, the material film causes a strong shear and mixing effect, which reduces the viscosity of the liquid to be treated, suitable for processing viscosity up to 50Pas, and Prevent scaling on the heating surface, especially suitable for liquids containing solids.

Extremely thin distilled liquid surface: The function of the film scraper scrapes the feed liquid into an extremely thin liquid film. The separation is more thorough. Heat sensitive materials:

High separation ratio: The precise scraper uses an extremely thin liquid film to be evenly distributed on the heating surface, resulting in the entire heating surface being wetted. This allows the operating unit to have a high boiling separation ratio. This means that in cases where more than 90% of the incoming material is evaporated, a constant residual material level can be achieved.

Advantages of short path distillation apparatus:

Short path distillation apparatus When the liquid mixture flows along the heating plate and is heated, the light and heavy molecules will escape from the liquid surface and enter the gas phase. Since the free paths of the light and heavy molecules are different, the molecules of different substances will escape from the liquid surface. The moving distance is different. If a condensing plate can be properly installed, the light molecules will reach the condensing plate and be condensed and discharged, while the heavy molecules will not reach the condensing plate and be discharged along the mixed liquid. In this way, the purpose of material separation is achieved.

In the process of mass transfer, the short path distillation apparatus can be adjusted at any time and control the more suitable temperature and vacuum pressure conditions in the equipment. The column in the equipment is designed with a relatively special anti-thermal stress expansion wrinkle section, which can It is very effective in preventing the unsafe factor of abrupt change in the temperature difference of the column.

During the operation of the short path distillation apparatus, the condensing surface and the thin surface of the equipment will directly form its pressure difference. The pressure difference formed is the driving force of the entire steam flow direction. The small pressure drop in the equipment will directly cause the steam to In the case of flow, the distance between the condensation surface and the boiling surface is relatively short when the molecular short path distillation is running.

In the selection process of short path distillation apparatus, it is necessary to choose an economical and reasonable distillation temperature, so that the material will have better stability during processing. There may be collisions between them.

The short path distillation apparatus can avoid the traditional method of heat exchange between the operating environment and the columns, which will directly cause the error of the experimental data caused by the overheating of the equipment or the artificial destruction of its balance caused by heat preservation.

The strength of the short path distillation apparatus is very high during operation. Such equipment has strong corrosion resistance during use. Such products are very suitable for most reagents and chemical materials. performance.

In the process of design, very advanced design concepts and manufacturing processes are adopted. The core component of the short-path distillation equipment is the distillation column. The structure of the equipment is directly related to the separation effect of the equipment in the process of use.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.