News

Industrial Short Path Distillation

What is industrial short path distillation?

In industrial and chemical fields, individuals at all times have to extract some solvents or purify some substances. There are a number of methods to attain those and industrial short path distillation is certainly one of them. Industrial short path distillation is a way that removes solvents from mixtures by way of evaporation. Industrial short path distillation is principally used for liquid-liquid separation.

The quick path distillation refers to a type of Industrial short path distillation and distillation tools. As a type of thermodynamic separation technology, the tools can evaporate elements with low boiling points by utilizing that the boiling level of every part in the mixed liquid or liquid-solid mixture is different, after which condense the fabric to separate the whole components. It is the mix of evaporation and condensation unit operations as well as a sort of liquid-liquid separation expertise.

What is industrial short path distillation Used for?

Industrial short path distillation is broadly used in varied features of the nationwide economy, particularly for the separation of high boiling level and heat delicate and easy oxide materials. The functions could be concluded as follows:

Distillation and concentration. Industrial short path distillation methods are used in pure and artificial vitamins, wool fatty acids, lanolin, palm oil, rice bran oil, fish oil and cod liver oil, pure plant leaf root extract (such as capsanthin, lycopene, pyrethrin, The application of lecithin, b-carotene, lively elements of conventional Chinese medication, etc.

Removal of solvent. With the development of recent domestic and international standards and the continual improvement of people’s residing requirements, the restrictions on solvent residues in chemical raw materials and their merchandise closely associated to human beings similar to meals, medication, cosmetics and constructing materials are becoming increasingly more strict. Traditional distillation methods have been unable to meet the wants of the market, and this kind of process typically follows the extraction methodology as the last quality assurance system for green products.

Decolorization and deodorization. Typical examples are: organic intermediates, lactic acid, fatty acids and derivatives thereof, APG, epoxy resins, epoxidised oils, vegetable waxes, silicone oils, brake fluids, vacuum pump oils, lubricating oils, paraffin oils, and so on.

Preparation/production of high-boiling process materials and dedication of boiling vary. Industrial short path distillation expertise can achieve distillation separation in a vacuum of zero.001 mbar and a heating time of less than 1 minute, so it's undoubtedly the preferred know-how for distillation separation for those heat-sensitive high-boiling substances.

Advantages of industrial short path distillation:

The industrial short path distillation is type of appropriate for heat-sensitive compounds. The distilling temperature used for industrial short path distillation could be much decrease than the boiling point of the compound because of it is operated underneath negative pressure.

The industrial short path distillation has a fast heating course of. It only requires a number of seconds to complete the distillation course of, while other conventional distillation apparatuses take hours to complete a distillation.

The industrial short path distillation can successfully scale back material waste. The liquid is simply must journey a brief distance by adopting short path distillation. Hence less compound is misplaced in the course of the distillation process.

The quickindustrial short path distillation is much simpler to make use of. It can achieve high distillate purity ranges without massive and sophisticated apparatuses compared to typical distillation techniques. It implies that short path distillation doesn’t require large working spaces.

In the industrial short path distillation, pattern can get heated and evaporated within the specialised evaporation flask. Then gas-phase extracted solvents shall be transferred alongside the brief distance and be condensed into liquid-phase throughout this distance. Finally, the liquid-phase extracted solvents will go into receiving flask and be collected there. It is handy for users to take the extracted solvents away from receiving flask.Industrial short path distillation may be very handy and high-efficiency for customers to extract or purify substances.

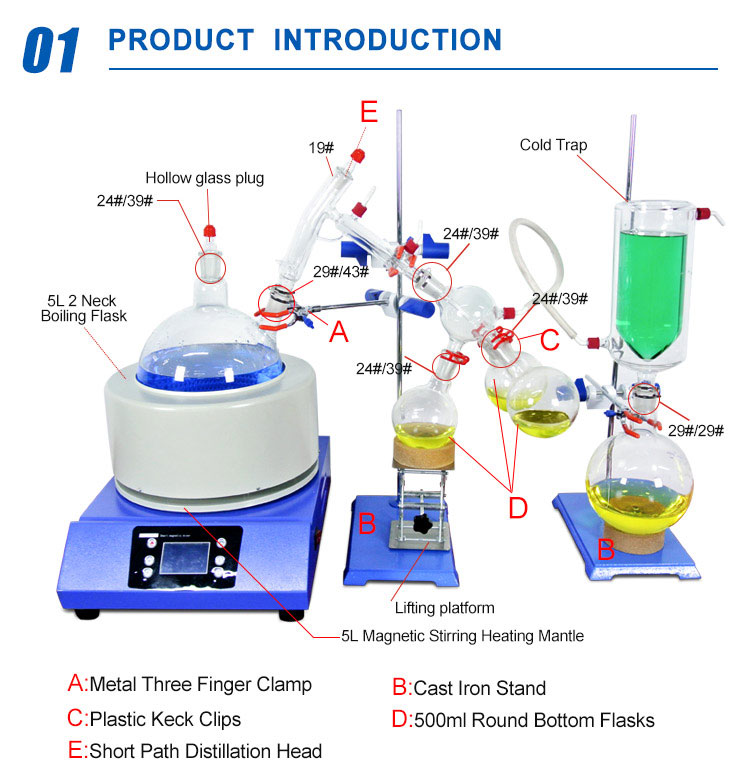

Supporting equipment:

Chiller:

The time period"chiller"can be miss-leading when speaking about short path. A vapor may be recondensed at a temperature that's no much less than 20 levels colder than what's was boiled off at. For instance, a compound boiled off at 400F might be recondensed at 380F. The 380F temp is"colder"than the 400F that the compound boiled off at however, that is certainly not really cold. When doing industrial short path distillation, the temp vary might be about 100C to 250C (212F to 482F) on the heating mantle. This means the quick path condenser will be set between 40C and 60C. We prefer 50C (122F) for a place to begin (temp differentials concerning specific fractions shall be mentioned in a sophisticated post). This means we do not neccessarily want a"chiller”. We simply want a tool that can maintain our desired 50C temperature through the process. This 50C temp will maintain our brief path from clogging and shall be"chilly"sufficient to simply recondense any vapors that travel into the trail of the condenser.

Vacuum Pump:

When doing a distillation process, it's crucial that you've a chemically resistant vacuum pump that may acheive extreme depth. The pump ought to have the flexibility to obtain at least 50 micron but the deeper the higher. The most well-liked sort of pump for distillation is a rotary vane (oil) pump. Rotary vane pumps offer the best vacuum depth in comparability with other kinds of pumps (specialty pumps similar to diffusion pumps might be mentioned in a later post). Industrial short path distillation can be very chemically abrasive to your vacuum pump. For this reason it is suggested to vary your oil earlier than every distillation. This will allow you the most effective depth and keep your vacuum pump operating at peak efficiency.

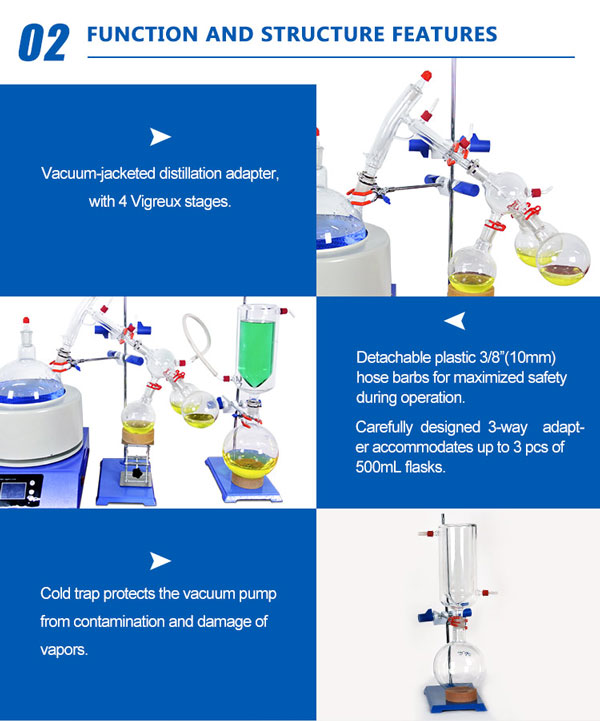

Cold Trap:

The chilly lure performs the essential position of catching any vapors that cross through the condenser. This protects and prolongs the lifespan of your vacuum system.

Short Path:

The Short path itself is made up of 4 major glass parts and the heating mantle. These components are: the boiling flask, the quick path head, the receiving cow, and the receiving flasks. The heating mantle is much like a heat bath on the rotovap. This is how you'll heat the mixture contained in the boiling flask. The head is the vital thing to distillation. Inside the pinnacle there are small indentations known as"vigreaux”. These create contact factors for the vapors to bump as they travel up into the head. They create"theoretical plates"needed for distillation the place vapors will become purified before coming into the condenser path. The head also encompasses the condenser where the vapors will be pulled to re-condense into that beautiful golden shade all of us wish to see. The three receiving flasks correspond to the three primary fractions.

Applications of industrial short path distillation

Industrial short path distillation is used in research and development fields such as pharmaceuticals, petrochemicals, and organic chemistry, and is also used in the production and purification of pilot, small-scale, and high-value-added products before industrialization. Distillation devices are also important in the separation, purification, and concentration processes of chemical products. They are necessary equipment for colleges and universities and scientific research institutes to study important topics in material mass transfer, heat transfer processes and principles, and are also essential for establishing product separation and purification methods and screening process conditions. important tool.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.