News

Short path distillation thc equipment selection|Short path distillation manufacturer

What is distillation?

Distillation: is a thermodynamic separation process that utilizes different boiling points of various components in a mixed liquid or liquid-solid system to evaporate low-boiling components and then condense to separate the entire component of the unit operation process, which is evaporation and condensation. A combination of unit operations.Principle: Using the difference in volatility of the components in the liquid mixture, the liquid mixture is partially vaporized and the vapor is partially condensed to achieve separation of the components contained therein. It is a unit operation that belongs to mass transfer separation. Widely used in refining, chemical, light industry and other fields. The principle is as an example of separating a two-component mixture. The liquid is heated to partially vaporize it, the volatile components are concentrated in the vapor, and the less volatile components are also concentrated in the remaining liquid, which achieves the separation of the two components to some extent. The greater the difference in the volatilization ability of the two components, the greater the degree of enrichment described above. In an industrial rectification plant, a partially vaporized liquid phase is directly contacted with a partially condensed gas phase for vapor-liquid phase mass transfer, and as a result, a partially volatile component in the gas phase is transferred to the liquid phase, and the liquid phase is easy. Part of the volatile component is transferred to the gas phase, that is, partial vaporization of the liquid phase and partial condensation of the vapor phase are simultaneously achieved.

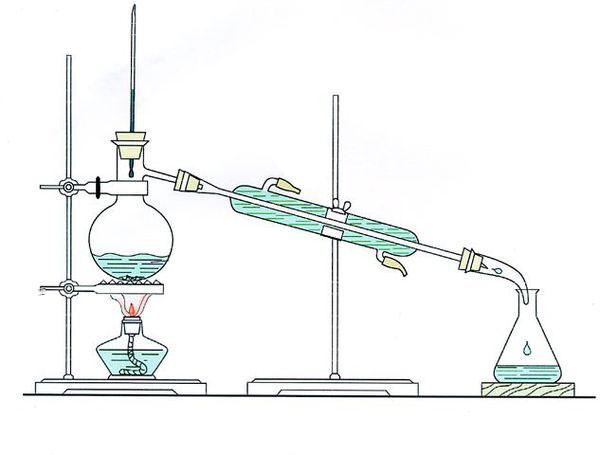

The picture above shows the simplest distillation unit. Only simple distillation reactions with low dissolution points can be done. Some of the more complex experimental reactions with high material dissolution points cannot be completed.

The short-path distillation produced by our company is a high-precision distillation unit. The distillation system has a simple structure, small footprint, high evaporation efficiency, high recovery efficiency and fast heating. It can be heated to 300 ° C, which can solve the dissolution problem of most experimental reaction materials.

The short-path distillation produced by our company is a high-precision distillation unit. The distillation system has a simple structure, small footprint, high evaporation efficiency, high recovery efficiency and fast heating. It can be heated to 300 ° C, which can solve the dissolution problem of most experimental reaction materials.

What is short-path distillation?

The short path distillation system is a distillation technique involving the distillate traveling a small distance, only a few centimeters away, usually under reduced pressure. Can be used in food, pharmaceuticals, fine chemicals, electronic materials, plastic engineering and polymers (such as polyols, fatty acids, polyphenols, polyurethanes, epoxies, lactic acid, monoglycerides, flavors, heavy oils and paraffin oils) Separation and purification.

Distillation, solvent recovery operation procedures

1. According to the production process requirements or the nature of the materials, choose the distillation method (normal pressure distillation, vacuum distillation), and check whether the pipeline connection method is correct.

2. Before opening the system control valve, check whether the performance of the equipment and each control valve is intact.

3. Check the steam before heating, confirm the steam, reaction kettle and various pressure gauges on the corresponding pipeline. The indication of the thermometer is normal.

4. At atmospheric pressure distillation, it is necessary to check the venting valve of the piping system and the condenser circulating water control valve should be opened; the vacuum distillation must check whether the vacuum pressure of the pipeline meets the process requirements.

5, distillation heating operation should be slow (about 30 to 1 hour), to prevent rapid heating and "punching", "bumping" occurs.

6. During the distillation process, it is necessary to observe the reduction of the materials in the kettle and timely replenish it; observe the changes in the pressure gauge and the temperature gauge to ensure that the production process requirements are met.

7. During the distillation operation, it is necessary to observe whether the entire system leaks at any time, and prevent the occurrence of “running”, “rising”, “dropping” and “leakage”.

8. Pay attention to observe the running condition of the equipment to prevent the reducer from running without oil or overload.

9. After the operation, collect the distilled solvent and mark it; clean the equipment and pipeline, and fill in the operation record in time.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.