News

The circulating water vacuum pump produced by our company has the advantages of small size, light weight and many uses.

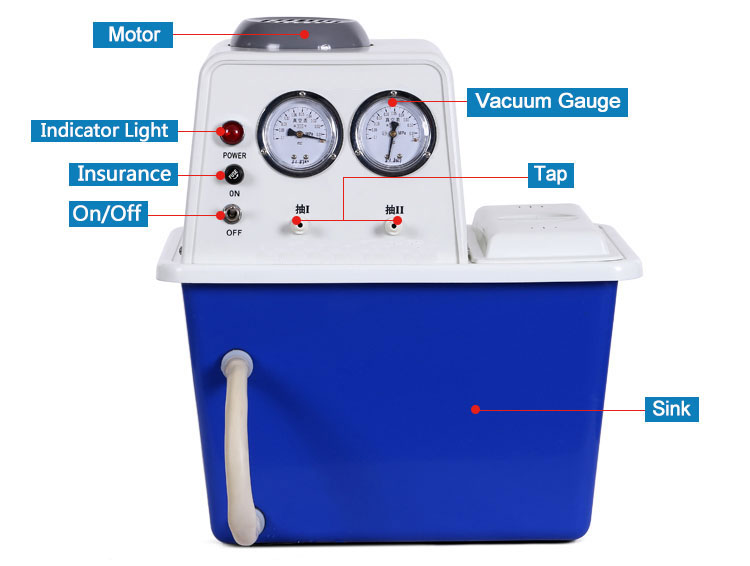

SHZ-D (III) Desktop Circulating Water Vacuum Pump

SHZ-D (III) Desktop Circulating Water Vacuum Pump is vacuum pump for short path distillation equipment, which can perfectly help short-path distillation to complete vacuum distillation. Is a vital equipment in short-path distillation systems.

SPD-5 L single receiving bottle short path distillation

How SHZ-D (III) works:

The series of multifunctional circulating water vacuum pumps use circulating water as the working medium, and use the negative pressure generated by the fluid jet to spray.

Application field of SHZ-D (III)

It provides vacuum conditions for evaporation, distillation, crystallization, drying, sublimation, filtration, decompression, degassing, etc. It is especially suitable for laboratories and small-scale experiments in universities, research institutes, chemical industries, etc. Pharmaceutical, biochemical, food, pesticide, agricultural engineering, bioengineering.

SHZ-D (III) circulating water vacuum pump specifications

| Model | SHZ-D (Ⅲ) |

SHZ-D(Ⅲ) four-meter, four tap |

Remark |

| Power (W) | 180 | 370 | Can equipped with 2L, 5L glass reactor or short-path distillation. The vacuum is better when the water temperature is between 4℃ and 10℃. |

| Voltage (V/Hz) | 110/50/60 | ||

| Flow (L/min) | 60 | ||

| Lift (m) | 8 | ||

| Body material |

Anti-corrosion /1Cr18 |

Anti- corrosion |

|

| Max. pressure (Mpa) | 0.098 | ||

|

Sucking rate for single tap(L/min) |

10 | ||

| Quantity of tap (Pcs) | 2 | 4 | |

| Tank capacity (L) | 15 | ||

| Dimension(mm) | 400*280*420 | ||

| Weight(kg) | 15 | ||

| Ultimate vacuum (kpa) | 26 | ||

| Security performance | Anti~corrosion, counter~current prevent valve | ||

Characteristics of SHZ-D (III)

1. Acid, alkali and solvent corrosion.

2. The special machine is made of the famous electrical manufacturing ODM. The fluoro rubber is sealed and the inside will not be invaded by corrosive gases.

3. The special fluid muffler can reduce the gas in the water, make the vacuum higher and more stable; reduce the friction between the gas and the fluid, and reduce the noise.

4. Double-click or four-tap, each vacuum gauge displays the corresponding tip vacuum.

5. Recycle water to save valuable water resources.

6. Save more than 35% of electricity compared to other types of vacuum pumps.

7. Can be used to extract corrosive gases, shorten the water change cycle.

8. The water in the tank needs to be replaced regularly to ensure water quality, vacuum and purity.

How is SHZ-D (III) operated?

1. Add enough circulating water. Place the machine on the workbench stably. Use it first. Please turn on the water and add the ice. Then, pour the tap water and observe that the water level is floating. When the water level reaches the optimal water level, stop adding water.

2. Boot up. Please connect the power cord between the machine and the power supply correctly.

3. Vacuum operation. Place the suction tube firmly on the nozzle, check that the circulating water switch is off, and then read the indicated vacuum.

4. Provide circulating cooling water. When it is necessary to supply circulating water to the reaction device, the circulating cooling water can be supplied by contacting the circulating water device with a casing and then starting the water circulation switch.

5. Beyond the natural circulation. When the machine needs to run for a long time, in order to prevent the temperature of the circulating water from rising and affecting the vacuum effect, we can use the hose connected to the water to properly control the flow of tap water to form a natural circulation state. We must also constantly replenish and replace the cooling water to keep the circulating water temperature from rising and will not affect the vacuum effect.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.