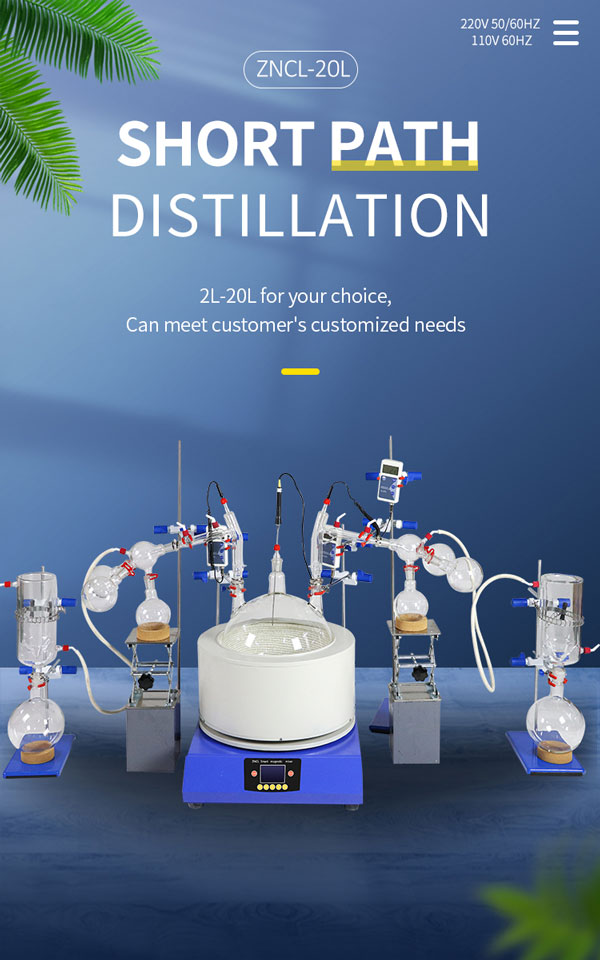

Short distillation

Double 20L Short Path Distillation Kit

Introduction Of Double 20L Short Path Distillation Kit

Double 20L short path distillation kit (Short Path Distillation) is an efficient distillation technique for separation and purification of liquid mixtures. Compared with traditional distillation, the Double 20L short path distillation kit can achieve a faster and more efficient separation process by shortening the distillation path and reducing the residence time of the distillate in the equipment.The principle of the Double 20L short path distillation kit is based on the lowering of the boiling point of liquids at low pressure. By creating a vacuum environment during the distillation process, the boiling point of the liquid can be lowered, thereby reducing the influence of temperature on the thermal sensitivity of the substance, especially suitable for dealing with high boiling point, easily degraded or sensitive compounds.

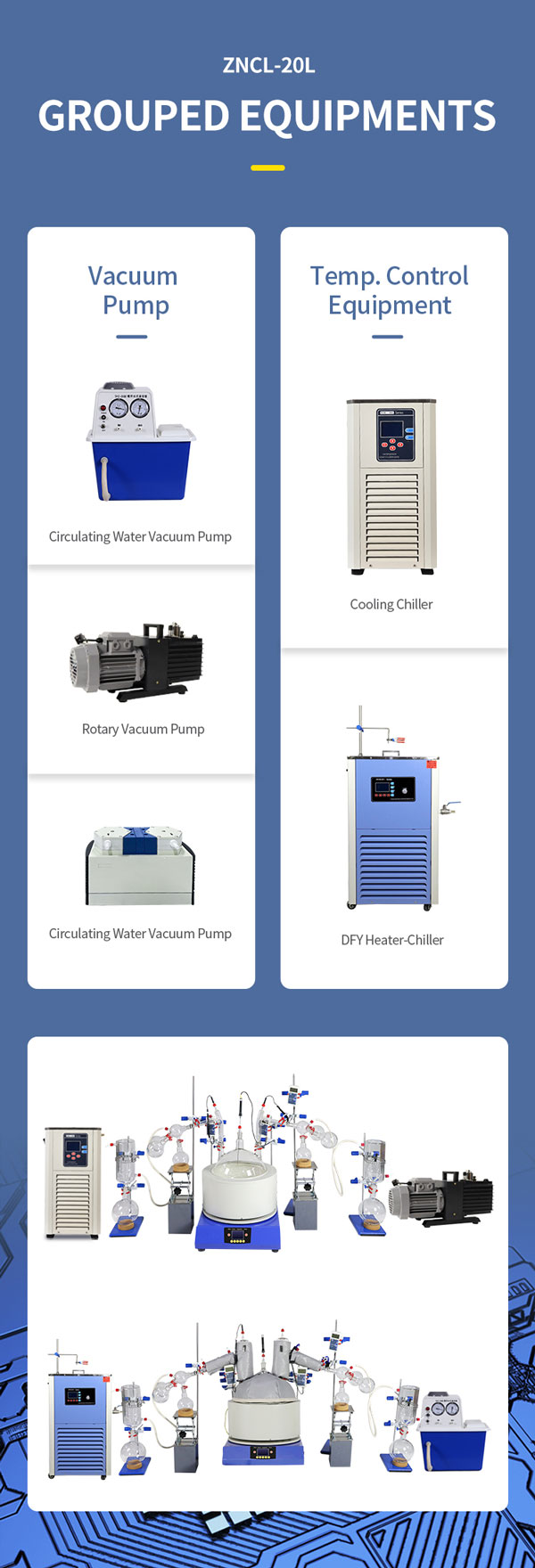

Grouped Equipment

DLSB-20/40°C low temperature coolant circulation pump.

Capacity: 20L; Minimum no-load temperature: -40°C; Power 100WDLSB-20/40°C Low Temperature Coolant Circulation Pump is a commonly used experimental instrument in the laboratory, used to circulate low temperature coolant or refrigerant.

SHZ-C circulating water vacuum pump.

Capacity: 50L, SHZ-C circulating water vacuum pump is used to extract air and other gases from the sealed system to create a vacuum environment, often used in conjunction with other laboratory equipment (such as rotary evaporators, vacuum drying ovens and filter equipment) To facilitate various laboratory procedures.

Double 20L Short Path Distillation Kit Structure

Distiller:

A decanter is a container in which a mixture to be distilled is placed. It is usually a round bottom flask with appropriate capacity and connections.Distillation head:

The distillation head is the part that connects the distillation bottle and the condenser. It is usually a glass construction with an inlet and an outlet. The design of the distillation head helps direct the distillation product to the condenser and prevents backflow.Condenser:

The Double 20L short path distillation kit is equipped with two condensers to cool down the vapor produced by distillation to make it liquid again. It is usually a tubular structure, and the cooling effect is achieved by a cooling medium (such as cold water or coolant) inside.Liquid outlet:

The liquid outlet is where the pure product flows from the condenser. This port is usually located at the bottom of the condenser and connects to a collection vessel (such as a receiver bottle).Heating system:

Double 20L short path distillation kit needs to provide a heating source to heat the mixture in the distillation bottle. This could be a heating mantle, heating chamber, or other form of heating device.Temperature control system:

To precisely control the temperature during distillation, temperature control systems such as thermistors, thermometers and controllers are often used.Vacuum system:

Double 20L short path distillation kit is usually carried out under vacuum to reduce the distillation temperature and reduce the volatilization of harmful substances. Vacuum systems include vacuum pumps, gauges and associated piping and fittings.Interfaces and Connectors:

In order to assemble the entire Double 20L short path distillation kit system, it is usually necessary to use various glass interfaces, connectors and fixtures.

Application Of Double 20L Short Path Distillation Kit:

Chemical Manufacturing:

Double 20L short path distillation kit can be used in separation and purification process in chemical manufacturing. It can separate different components in a mixture, remove impurities and residual solvents, and obtain high-purity compounds.Pharmaceutical Industry:

In the field of pharmaceuticals, Double 20L short path distillation kit is often used to extract active ingredients of drugs, separate and purify drugs, and remove unwanted impurities. It can be used in the preparation of pharmaceutical intermediates, the purification of synthetic drugs, solvent removal, etc.Spice and Essential Oil Extraction:

Double 20L short path distillation kit can be used to extract spices and essential oils from natural plants. By controlling temperature and vacuum conditions, volatile components with specific odor and medicinal properties can be separated and collected.Food and Beverage Processing:

Double 20L short path distillation kit has various applications in the food and beverage industry. It can be used to extract flavor and flavor compounds from food ingredients, remove unwanted components, or extract alcohol from beverages.Oil and Fatty Acid Purification:

Double 20L short path distillation kit can be used to purify oil and fatty acid, remove impurities and impure substances. It plays an important role in the refining of vegetable oils and the processing of animal fats.Petroleum and Chemicals:

In petroleum and chemical industry, Double 20L short path distillation kit can be used for fractionation of petroleum products, purification and separation of petrochemical products, and treatment of high boiling point substances.Environmental Analysis:

Double 20L short path distillation kit is used in environmental analysis to extract and separate organic pollutants in environmental samples, such as volatile organic compounds (VOCs) and persistent organic pollutants (POPs).| SPD-20L Short Path Distillation Kit | |

| ZNCL-T-20L Heating Mantle | Magnetic stirring heating mantle ▏20L ▏1800W ▏380 ℃ |

| Boiling Flask Sizes | 20L ▏80mm Flange Main ▏24/40 Side |

| Distillation Head Joint Sizes | 80mm Flange Bottom ▏34/45 Top ▏34/45 Side |

| Condenser Joint Sizes | 34/45 Inlet ▏34/45 Outlet |

| Isolation Adapter Joint Sizes | 34/45 Inlet ▏34/45 Outlet ▏29/40 Bottom Discharge |

| Receiving Flask | 5000ml * 1 ▏29/40 |

| Cold trap Joint Size |

34/45 Inlet ▏34/45 Outlet ▏ 2L round bottom flask with 35 ball joint |

| Clamp | Cross clamp*5 ▏Three-finger clamp*2 |

| Thermometer | Digital thermometer *1 |

| Other Parts | Iron stand ▏Lab jack ▏Cork ▏Hose fitting ▏Tubes ▏Clips |

| Batch Time | 4-10 Hours |

| Optimal Capacity | 7000 - 12000 ml |

Q:Why is the distillation rate so slow?

A:Check that the vacuum pump is functioning properly to ensure an adequate vacuum level.Check if the condenser is blocked, clean the condenser to improve cooling efficiency.

Check to see if the decanter is not overfilled, the amount of mixture may need to be reduced.

Check that the heating source is working properly to ensure proper heating temperature.

Q:Why is the purity of the distillation product not high?

A:Make sure the mixture in the retort is pure enough to reduce the amount of impurities.Check that the condenser is working properly to ensure sufficient cooling to prevent backflow and carryover of impurities.

Ensure correct distillation temperature and vacuum level to avoid degradation or volatilization of target compounds.

Q:Why the violent foaming and spilling?

A:Check for excess liquid in the decanter to ensure proper capacity.Check for gas bubbles from excess volatile components, may require lowering distillation temperature or adjusting vacuum level.

Check the condenser for overheating, it may be necessary to increase the cooling effect or reduce the feed rate.

Send Us Message

Your message was sent successfully.

Sorry!Something Went Wrong.